The selection of a Crane Drum primarily involves considering the following factors:

- Load Capacity: When choosing the drum, it is essential to ensure that it can bear the weight lifted by the crane. The drum’s diameter and material should be selected based on the crane’s maximum load capacity to ensure safety and durability.

- Wire Rope Specifications: The drum design must match the wire rope selected. The diameter, strength, and groove size of the drum must be determined according to the specifications of the wire rope. This ensures that the wire rope does not get damaged or worn out during winding.

- Working Environment: If the crane operates in a harsh environment (e.g., high temperatures, high humidity, or corrosive gases), it is necessary to choose a drum with strong corrosion resistance. For high-temperature environments, both the drum material and lubrication system must be carefully considered.

- Drum Material: Drums are typically made of high-strength steel or alloy steel. When selecting the material, its corrosion resistance, wear resistance, and fatigue resistance should be taken into account.

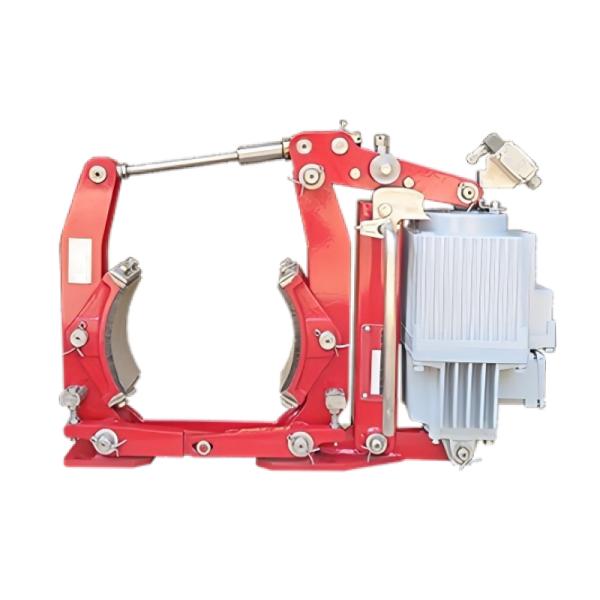

- Drum Drive Method: The drum can be driven either electrically or hydraulically. An electric drum requires a suitable motor, gearbox, and transmission system, while a hydraulic drum necessitates a properly designed hydraulic system. The choice should align with the crane’s operational requirements.

- Drum Size: The size of the drum, including its diameter and length, directly impacts the crane’s performance. The drum diameter is typically proportional to the wire rope diameter, and it must ensure the wire rope winds evenly around the drum.

- Fatigue Resistance: During crane operation, the drum endures repeated loads. Therefore, it is crucial to ensure that the drum has excellent fatigue resistance to prolong its service life.

- Crane Operating Cycle: Different cranes have different operational cycles. Some cranes may need to lift and lower loads frequently, while others may handle lighter loads. When selecting the drum, the crane’s frequency and load should be considered to ensure the drum can operate reliably under high-frequency and high-load conditions.

In the selection process, it is advisable to have detailed discussions with equipment suppliers or engineers, ensuring that the chosen drum meets the actual operational requirements and provides an adequate safety margin.