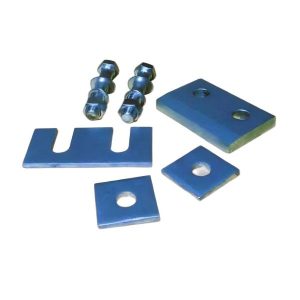

WJKC Rail Clips

Specifications of WJKC Rail Clips

- Models: WJKC1, WJKC2, WJKC3

- Fixing Method: Welded base plate

Features of WJKC Rail Clips

- Primary Applications:

WJKC rail clips are primarily used for securing crane rails with horizontal guiding wheels on steel crane beams, as well as for fixing tracks of large-tonnage soft-hook cranes. - Ease of Installation:

The design facilitates easy installation, adjustment, and replacement of the rails. - No Drilling Required:

These clips eliminate the need for drilling into crane beams, as they are directly welded onto the upper flange of the crane beam. - Double Bolt Connection:

The WJKC fixing devices exclusively use a dual-bolt connection for enhanced stability and reliability. - Load-Bearing Capacity:

- WJKC1: Handles a maximum lateral force of 135kN from horizontal guiding wheels.

- WJKC2: Handles a maximum lateral force of 220kN.

- WJKC3: Handles a maximum lateral force of 400kN.

Selection Considerations for WJKC Rail Clips

- For crane tracks with horizontal guiding wheels, it is mandatory to use special composite rubber pads along the full length beneath the rail.

- Tracks without horizontal guiding wheels should not be installed.

- QU120 rails are recommended for large-tonnage cranes, although other rail types can be considered in special cases.

Installation Sequence and Key Points for WJKC Rail Clips

- Base Alignment:

Use the three grooves on the surface of the fixed base and the center of the rail clamp to position it. The allowable deviation from the crane beam centerline is 1.00mm. - T-Bolts:

Insert the T-bolts and slide them into position toward the rail. - Adjustment Plate:

Ensure the grooved side of the adjustment plate faces upward during installation. - Component Assembly:

Sequentially install the pressing plate, washers, spring washers, and nuts. - Alignment and Tightening:

- Adjust the wedge-shaped adjustment plate to ensure the rail clamp is perpendicular to the rail.

- Tighten the bolts once the pressing plate fits snugly against the lower flange of the rail.

- Torque specifications: 256N·m for WJKC1 and WJKC2, 423N·m for WJKC3.

- Stress Reduction:

To minimize welding stress, use techniques such as symmetric welding, reverse welding, or skip welding. - Angle Adjustments:

When designing and installing, consider how the fixed base plate may affect the angle of the crane beam.