WJK Rail Clips

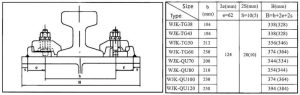

Specifications of WJK Rail Clips

- Models: WJK-TG38, WJK-TG43, WJK-TG50, WJK-TG60, WJK-QU70, WJK-QU80, WJK-QU100, WJK-QU120

- Fixing Method: Welded base plate

Features of WJK Rail Clips

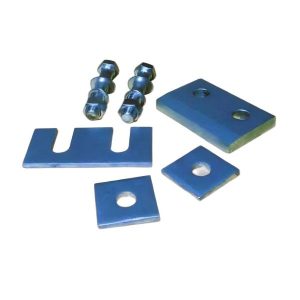

The WJK rail clips are designed for steel beams, with a lifting capacity of 350 tons per set, comprising seven components in total.

- Base Plate Welding:

The WJK base plate is welded to the steel crane beam’s flange either with three-side surrounding welds or two-side lateral welds. This configuration ensures the horizontal lateral force of the crane is smoothly transferred to the crane beam. Moreover, it eliminates the structural weakening caused by excessive drilling on the flange, thereby significantly enhancing the crane beam’s cross-sectional load-bearing capacity. - Ball Joint Connection:

The base plate connects to the lower end of the T-bolt through a ball joint. Consequently, the T-bolt remains perpendicular to the upper cover during lateral force application and allows for slight tilting. This design effectively mitigates the lateral impact of the crane on the rail, crane beam, and braking system, ultimately prolonging the structural service life. - Gauge Adjustment Plate:

The WJK clips include a gauge adjustment plate for fine-tuning the rail gauge. This feature enhances installation precision, reduces deviations in the rail centerline, and incorporates a dual self-locking mechanism to prevent loosening during use. - Ease of Installation and Maintenance:

The T-bolts and upper cover plates of WJK clips can be easily assembled and disassembled, providing great convenience during construction and maintenance operations. - Compatibility with Rail Curvature:

The upper cover plate matches the curvature of the rail cross-section, enabling it to tightly secure the rail without hindering its slight longitudinal movement. This feature also facilitates the welding of full-length rails. - Fixed Component Spacing:

The spacing of the fixed components is determined by the crane’s lifting capacity. For loads ≤275t, the spacing is 600mm; for loads >275t, the spacing is reduced to 500mm. - Welding Material Compatibility:

The base of the fixed component is welded to the crane beam using electrode models compatible with the material of the connecting components. For example, E4303 electrodes are used for Q235 steel, while E5015 electrodes are used for Q345 steel. - Weld Types Based on Crane Duty:

Medium-duty cranes use two-side weld seams, while heavy-duty (or super-heavy-duty) cranes require three-side surrounding weld seams. - Bolt Tightening Torque:

For medium-duty cranes (Q ≤ 275t), the maximum bolt tightening torque is 150N·m. For heavy-duty cranes, it is increased to 220N·m. - Maximum Lateral Force:

The maximum allowable lateral force for the rail clips is 45kN.