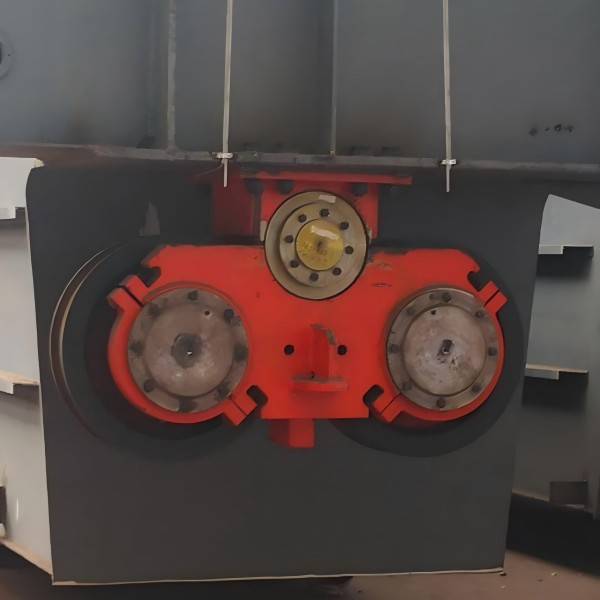

Round bearing box crane wheel

Round bearing box crane wheel Parameters:

- Specifications: Φ500, Φ600, Φ700, Φ800

- Wheel Material: ZG430-640, 45 steel, 50SiMn, 65Mn, 42CrMo

- Wheel Type: Double flange, Single flange, No flange

- Wheel Groove Width: Determined according to track model

- Custom Orders: We can manufacture based on your drawings and dimensions provided.

The Round Bearing Box Crane Wheel is an essential mechanical component, primarily responsible for supporting the crane and its load while allowing the crane to move back and forth along the track. The design and material selection of this wheel set significantly impact both the crane’s performance and its service life. Below are some key features and details about the Round Bearing Box Crane Wheel:

Material Selection

The wheel is typically made from ZG430-640 cast steel, a material renowned for its superior mechanical properties and wear resistance. To further enhance the wheel’s surface strength and longevity, the tread undergoes surface heat treatment. The surface hardness is required to be within the range of HB300-350, with a quenching depth of at least 20mm.

Structural Design

The Round Bearing Box Crane Wheel is composed of several key components, including the driving shaft, bearing box, bearings, wheel, shaft sleeves, and keys. The driving wheel set is connected to the reducer, motor, and brake system, which drives the idle wheel set. In the case of the trolley, the travel mechanism generally uses single-flange wheels.

Damage Types

Common types of damage to the wheel include wear, cracking of the hardened layer, and pitting. To mitigate track gauge errors caused during installation, the width of the wheel tread should be slightly wider than the track top width. Additionally, increasing the flange height can increase the contact area between the flange and the track side, reducing contact stress and thereby extending the wheel’s service life.

Application Scenarios

This wheel set is widely used in various types of lifting machinery, such as gantry cranes, bridge cranes, and others. Its design and manufacturing process account for various factors, including wheel load, driving methods, operating speed, and duty level, ensuring both safety and efficiency.

Maintenance and Care

Regular inspections of wheel wear are crucial to maintaining the wheels in optimal condition. Damaged or excessively worn parts should be promptly replaced. Additionally, maintaining clean and level tracks is vital for reducing extra wear on the wheels, ensuring stable crane operation.

In conclusion, the design and manufacturing of the Round Bearing Box Crane Wheels involve a complex process that considers multiple factors, with the ultimate goal of ensuring the crane’s safe and efficient operation.

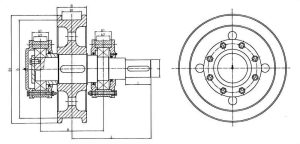

45° Split Circular Bearing Housing Wheelset

| Wheel diameter | Size (mm) | ||||||||

| D | D₁ | B | B1 | b | b₁ | H | h | d | |

| Φ500 | 500 | 540 | 150 | 100 | 230 | 50 | 310 | 140 | 75 |

| Φ630 | 630 | 680 | 150 | 100 | 230 | 50 | 310 | 140 | 85 |

| Φ710 | 710 | 760 | 150 | 100 | 235 | 80 | 350 | 160 | 90 |

| Φ800 | 800 | 850 | 150 | 100 | 275 | 90 | 410 | 190 | 95 |

Video

Faq

Q1: What are overhead crane wheels?

A1: Overhead crane wheels are key components that allow bridge cranes to move smoothly along the runway rails. They are designed to carry heavy loads, reduce friction, and ensure reliable crane operation in industrial environments.

Q2: What materials are overhead crane wheels made from?

A2: HLCRANE manufactures overhead crane wheels from high-quality steel plate with professional heat treatment. This process increases hardness, wear resistance, and durability, making the wheels suitable for continuous heavy-duty work.

Q3: Can overhead crane wheels be customized?

A3: Yes. HLCRANE provides customized overhead crane wheels based on diameter, tread width, bore size, and hardness. For detailed specifications and options, please visit www.hnhlcrane.com.

Q4: How do I know when overhead crane wheels need replacement?

A4: Signs of replacement include flange wear, surface cracks, and irregular running on the rail. Regular inspection is essential, and HLCRANE offers both standard and replacement wheels to ensure safe crane performance.

Q5: What industries use overhead crane wheels?

A5: Overhead crane wheels are widely applied in steel plants, foundries, shipyards, logistics centers, and heavy machinery workshops. HLCRANE wheels are trusted by clients worldwide for their reliability and long service life.