QJY crane gearbox

QJY Crane Gearbox Specifications

- Models: QJYD2, QJYD3, QJYD23, QJYD34

- Gear Ratios:

QJYD2: 6.3, 7.1, 8, 9, 10, 11.2, 12.5, 14, 16, 18, 20

QJYD3, QJYD23: 20, 22.4, 25, 28, 31.5, 40, 45, 50, 63, 80, 90, 100

QJYD34: 100, 125, 140, 160, 200, 224, 250, 280, 315, 335, 400

- Assembly Types: I, II, III, IV, V, VI, VII, VIII, IX

- Output Torque Range: From 1550 Nm up to 323,000 Nm

Overview of QJY Crane Gearbox

The QJY crane gearbox is a hard-tooth surface gearbox (carburized and quenched tooth surface) designed specifically for cranes. It is primarily used in various crane mechanisms but is also suitable for other machinery, including transportation, metallurgy, mining, chemical processing, and light industrial equipment, where reliable power transmission is essential.

Features

- Materials: The gears are made from high-quality, low-carbon alloy steel that is carburized and quenched, achieving a gear accuracy grade of 6.

- Performance: This gearbox is characterized by high precision, high efficiency, smooth transmission, and low noise. Compared to the QJ series tempered gearbox, it offers a more compact size, lighter weight, higher load capacity, and greater reliability.

- Structure: It features a welded housing and supports both three-point mounting and base mounting.

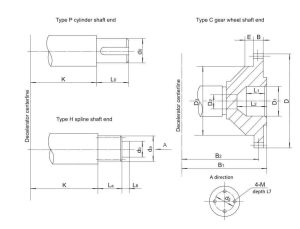

- Output Shaft Types: The output shaft is available in four configurations: flat key, involute spline, gear shaft end, and hollow shaft.

- Lubrication and Cooling: Typically, an oil sump lubrication system with natural cooling is used, though vertical gearboxes may adopt circulating oil lubrication. Rolling bearings are also used.

Operating Conditions

- Input Speed: Generally, n1<1500n_1 < 1500 r/min.

- Temperature Range: Operates effectively in temperatures ranging from -40°C to +50°C.

- Directional Operation: The gearbox is capable of bi-directional operation, making it adaptable to various crane gearbox types.

- Mounting Options: Available in multiple assembly configurations, enhancing versatility for different applications.

Assembly form

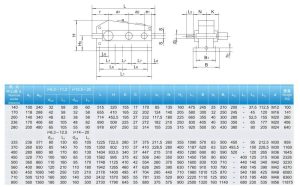

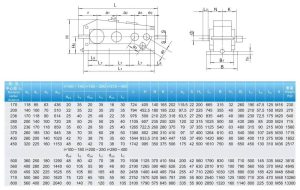

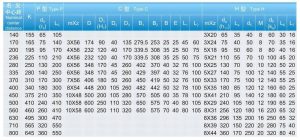

QJYD2: Shape and dimensions table

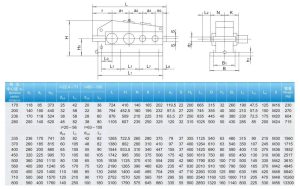

QJYD3: Shape and dimensions table

QJYD23: Shape and dimensions table

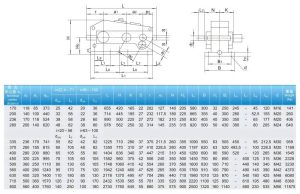

QJYD34: Shape and dimensions table

Output Shaft Types and Dimensions

allowable maximum radial loads for the gearbox’s output shaft

| Center distance | 140 | 170 | 200 | 236 | 280 | 335 | 370 | 400 | 450 | 500 | 560 | 630 | 710 | 800 | |

| Maximum permissible radial load(KN) | 2 | 9 | 15 | 21 | 28 | 35 | 43 | 55 | 60 | 75 | 100 | 107 | 120 | 150 | 170 |

| 3,4 | 9 | 15 | 28 | 35 | 48 | 55 | 64 | 93 | 120 | 150 | 170 | 200 | 240 | 260 | |