Overhead Crane Hook

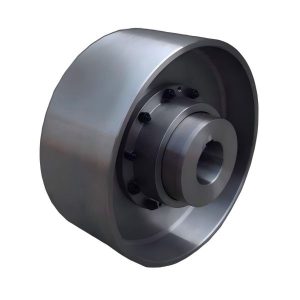

Overhead crane hook parameters:

- Specifications: 3.2t, 5t, 10t, 16t, 20t, 32t, 50t, 75t, 100t, 125t, 160t, 200t, 320t, 400t, 500t

- Working level: M3, M4, M5, M6, M7, M8

- Hook material: DG20, DG20Mn, 35CrMo

- Pulley cover type: semi-enclosed, fully enclosed

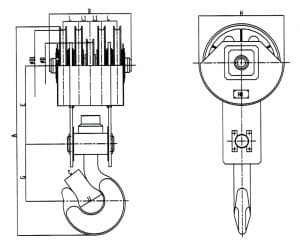

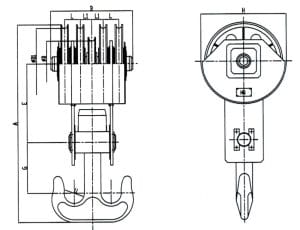

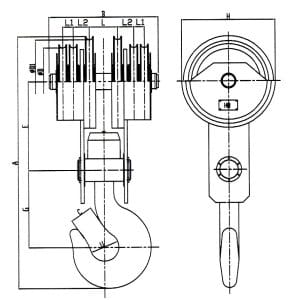

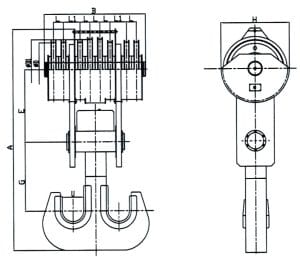

- Hook type: single hook, double hook, laminated hook

Overhead Crane hook introduction

- The crane operators use the Overhead Crane Hook as a key component for various lifting operations. They suspend it on the wire rope of the lifting mechanism using the pulley block and other components, and it bears the entire load of the lift. Designers and manufacturers must ensure the lifting hook meets safety standards to guarantee safety and reliability during operations.

- Many types of lifting hooks exist. Manufacturers divide them into forged hooks and laminated hooks based on manufacturing methods, and into single hooks and double hooks based on shape. The main difference between forged and laminated hooks lies in their manufacturing method, while single and double hooks differ in the number of hooks. In practice, operators use single hooks for loads not exceeding 75 tons and double hooks for heavier loads since double hooks have a higher bearing capacity.

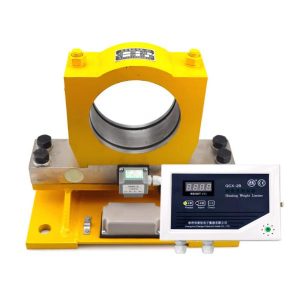

- When using lifting hooks, operators must conduct daily inspections and maintenance. This includes cleaning the hook assembly, checking the hook opening and wear in critical areas, examining the wear of the pulley groove and rim, ensuring the hook’s rotating part moves freely, and inspecting the anti-unhooking device.

- The safety and stability of the lifting hook significantly impact safe production. Therefore, users should regularly perform daily safety inspections and maintenance on the hook and conduct periodic inspections to ensure safe operations.

Please refer to the table below for Overhead crane hook selection

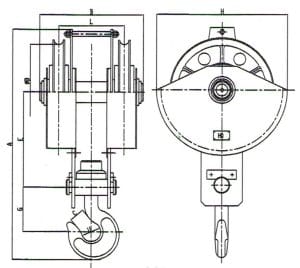

3.2t/5t 10t

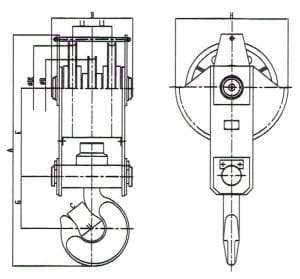

16t 20t/32t

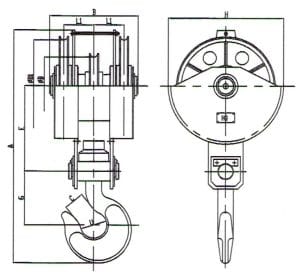

50t 75t

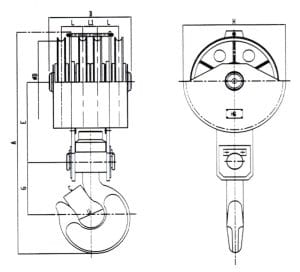

100t 200t

|

Specs |

Mandmensions(mm) | Wire rope parameters | Weight (kg) |

||||||||||||

| A | B | H | E | G | L | L1 | L2 | C | U | ØD1 | ØD | Diameter(mm) | Number | ||

| 3.2 | 775 | 350 | 420 | 320 | 150 | 220 | / | / | 50 | 65 | / | 300 | 11-14 | 4 | 80 |

| 5 | 858 | 370 | 480 | 320 | 184 | 240 | / | / | 65 | 85 | / | 350 | 11-14 | 4 | 100 |

| 10 | 1080 | 378 | 410 | 410 | 243 | / | 92 | / | 90 | 120 | 380 | 250 | 11-14 | 6 | 200 |

| 16 | 1330 | 506 | 485 | 485 | 307 | / | 172 | / | 115 | 150 | 500 | 310 | 14-20 | 6 | 330 |

| 20 | 1415 | 524 | 510 | 510 | 333 | 136 | 93 | / | 130 | 170 | / | 500 | 16-20 | 8 | 460 |

| 32 | 1740 | 604 | 620 | 620 | 420 | 155 | 105 | / | 160 | 210 | / | 610 | 18-22 | 8 | 845 |

| 50 | 1965 | 750 | 710 | 710 | 510 | 170 | 109 | / | 205 | 270 | 710 | 610 | 20-22 | 10 | 1500 |

| 75 | 2335 | 970 | 930 | 930 | 600 | 185 | 135 | / | 250 | 320 | 800 | 500 | 26-32 | 10 | 2500 |

| 100 | 3130 | 1360 | 1100 | 1100 | 955 | 350 | 131 | 200 | 270 | 355 | 1000 | 800 | 28-34 | 12 | 4200 |

| 200 | 3548 | 1617 | 1185 | 1185 | 1298 | 159 | 264 | / | / | 340 | 900 | 800 | 30-38 | 16 | 9100 |

Scrap standards

Scrap the hook if any of the following conditions occur:

- Cracks appear.

- The wear of the dangerous section reaches 10% of the original size.

- The opening increases by 15% compared to the original size.

- The hook body twists and deforms by more than 10°.

- Plastic deformation occurs in the dangerous section of the hook or the hook neck.

- The hook thread corrodes.

- Replace the bushing when it wears down to 50% of the original size.

- Replace the mandrel when it wears down to 5% of the original size.

Video

Faq

1. Who are reliable manufacturers of crane hooks?

HL CRANE is a professional crane hook manufacturer and supplier in China, offering high-quality hooks for overhead and gantry cranes. Visit www.hnhlcrane.com for more information.

2. Can the factory customize gantry crane hooks ?

Yes, HL CRANE’s factory provides OEM and customized solutions for gantry crane hooks, tailored to lifting capacity and working environment. Details at www.hnhlcrane.com.

3. What materials are typically used by crane hook suppliers?

Professional crane hook suppliers like HL CRANE use forged high-strength alloy steel with heat treatment to ensure durability and safety.

4. Which standards do crane hook manufacturers follow?

HL CRANE, as a certified crane hook manufacturer, produces hooks according to international standards such as ISO, FEM, and DIN. Each hook undergoes strict quality inspection. More info: www.hnhlcrane.com.

5. How can I order gantry crane hooks from a reliable supplier?

You can contact HL CRANE, a trusted crane hook supplier and factory, through the inquiry form or email.

6. What is the lifting capacity range of overhead crane hooks?

HL CRANE produces overhead crane hooks suitable for light to heavy-duty cranes, supporting a wide range of lifting capacities to meet different industrial needs. Learn more at www.hnhlcrane.com.

7. Are overhead crane hooks suitable for high-temperature or harsh environments?

Yes, HL CRANE overhead crane hooks can be designed for high-temperature foundries and harsh industrial conditions, ensuring safety and durability.