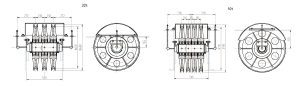

Overhead crane pulley

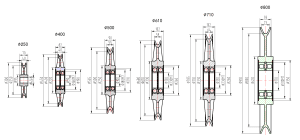

Parameters of Overhead Crane Pulley:

- Specifications: Φ250, Φ400, Φ500, Φ610, Φ710, Φ800, Φ900, Φ1000, Φ1200

- Pulley Material: HT20-40, ZG35, Q235B, Q355B

- Manufacturing Process: Cast iron, cast steel, rolled steel plate

- Pulley Groove Size: Determined according to wire rope diameter

- Non-standard Customization: We can manufacture according to drawings provided by you

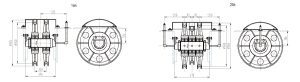

The composition of overhead crane pulley

The overhead crane pulley is an essential component of lifting machinery, achieving multiple functions through the combined use of fixed and movable pulleys, including lifting heavy objects, changing force direction, and reducing required effort. These pulleys are typically manufactured using different materials and processes, such as cast iron, cast steel, or rolled steel plate, to meet specific requirements for strength, wear resistance, and lightweight properties depending on the working conditions.

- Fixed Pulley: Primarily serves to change the direction of force without reducing effort. The principle of the fixed pulley is based on an equal-arm lever, where the power arm and resistance arm are equal, meaning it neither saves nor requires extra force to operate. In situations where rope weight and friction between the rope and pulley are negligible, the fixed pulley can keep the force direction of the rope constant, which is critical for the stable lifting of objects.

- Movable Pulley: Installed on the crane hook. When lifting a load with a movable pulley, it can save half the effort but requires pulling double the distance of wire rope. The principle behind the movable pulley is that the load is supported by two segments of rope, with each segment bearing only half the weight, thus providing an effort-saving effect.

- Pulley Block: Composed of multiple fixed and movable pulleys, it allows a combination of the force-saving benefit of the movable pulley and the directional change provided by the fixed pulley. This allows both force reduction and direction alteration, enabling more efficient lifting of heavy loads. The working principle of the pulley block is based on the combination of the effort-saving feature of the movable pulley and the direction-changing ability of the fixed pulley.

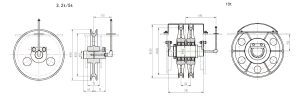

Overhead Crane Pulley Discarding Standards:

- Wear: If the wear on the pulley exceeds 10% of its original dimensions or affects the proper functioning of the wire rope.

- Cracks: The presence of cracks, especially in critical areas such as the groove or flange.

- Deformation: Noticeable deformation, such as in the groove or flange, which impacts normal operation.

- Fatigue Fracture: Occurrence of fatigue fractures in any part of the pulley.

- Corrosion: Rusting that exceeds 5% of the original dimensions.

- Looseness: Loose or damaged bearings.

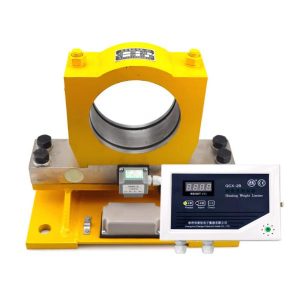

The cross-sectional shape and size of the grooves in the overhead crane pulley significantly impact its reliability and the service life of the wire rope. The groove walls should be smooth to avoid rope entanglement, ensuring safe operation.

Video

Faq

1. What is a crane pulley or sheave?

A crane pulley, also known as a sheave, is used in lifting systems to guide and redirect wire ropes or cables. HL CRANE manufactures high-quality crane pulleys in China. Learn more at www.hnhlcrane.com.

2. Who are reliable manufacturers of crane pulleys and lifting sheaves?

HL CRANE, a professional crane pulley and sheave manufacturer in China, provides durable products suitable for overhead cranes, gantry cranes, and hoists. Visit www.hnhlcrane.com for details.

3. Can the factory customize lifting pulleys for specific applications?

Yes, HL CRANE’s factory in China offers OEM and customized solutions for lifting pulleys, including different diameters, groove types, and load capacities.

4. What materials are used for industrial crane pulleys?

Crane pulleys and sheaves from HL CRANE are made of high-strength steel or cast iron, heat-treated for durability and reliable performance. More info at www.hnhlcrane.com.

5. How can I order wire rope pulleys from a trusted supplier?

You can contact HL CRANE, a reliable wire rope pulley supplier and factory in China, through the inquiry form or email on www.hnhlcrane.com.