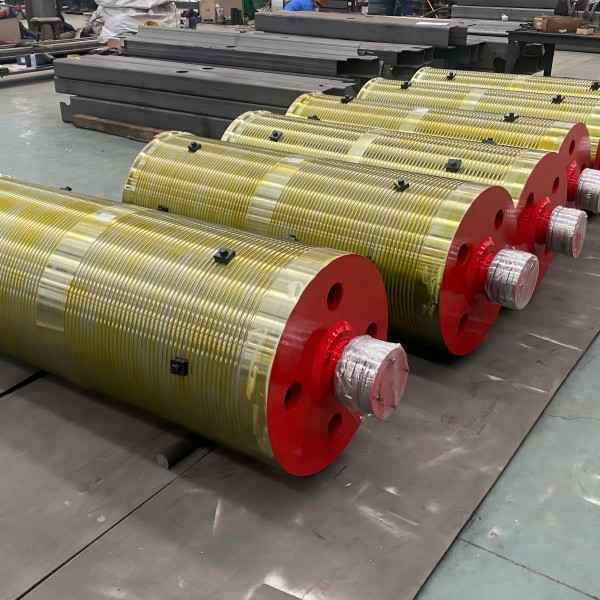

Overhead crane drum

Parameters of overhead crane drum:

- Specifications: Φ300×1000, Φ400×1500, Φ500×1500, Φ650×2000, Φ800×2000, Φ800×3600, Φ1000×3600

- Pulley Material: HT200, Q235B, Q355B,Q355E

- Drum connection: C-type gear plate, WZL drum coupling

- Drum manufacturing process: casting, steel plate rolling, seamless steel pipe

- Drum groove size: determined by the diameter of the wire rope

- Non-standard Customization: We can manufacture according to drawings provided by you

The composition of the overhead crane drum

The overhead crane drum serves as an essential component of lifting machinery, consisting primarily of a drum, drum shaft, gear disc coupling, drum hub, bearing housing, and bearings. It is used in the hoisting mechanism of cranes, where the low-speed shaft of the hoist gearbox is designed as a gear disc. Alternatively, the drum can also be used with a WZL drum coupling, in which the low-speed shaft of the hoist gearbox takes the form of a cylindrical shaft with a flat key. Furthermore, the design and manufacturing quality of the drum assembly directly affect the crane’s performance and safety. Therefore, the selection of its structure and material, as well as the manufacturing process, play crucial roles in ensuring the performance of the drum assembly.

- Structure and Material: The drum assembly is typically made from cast iron with a grade not lower than HT200. For special requirements, we may use ZG340-640 cast steel or Q235B, Q345B steel plates for welding. This selection of materials ensures the drum assembly’s strength and durability, allowing it to withstand various operational challenges.

- Manufacturing Process: The production of the drum assembly involves several steps, including sheet cutting, drum rolling, welding longitudinal seams, inspecting weld quality, and machining allowances. These processes ensure the accuracy and reliability of the drum assembly, thus meeting the high standards required for crane applications.

- Types and Applications: The drum assembly can be classified into different types based on usage requirements, such as single-layer winding, double-layer winding (grooved), and multi-layer winding. Additionally, based on the manufacturing method, the drum can be categorized as either a cast drum or a welded drum. Selecting the appropriate drum type is crucial to ensuring safe crane operation.

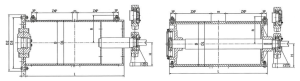

The basic parameters of the overhead crane drum:

The basic parameters of the overhead crane drum include the diameter, length, plate thickness, and other relevant dimensions of the drum assembly. These parameters directly impact the performance and applicability of the drum assembly, which in turn affects the crane’s overall performance and efficiency. The specific parameters are as follows:

-

- Diameter and Length: The drum’s diameter and length are fundamental dimensions that determine the drum’s wire rope capacity and, therefore, affect the crane’s lifting capacity. For example, a drum with a diameter of 800 mm and a length of 2800 mm has critical parameters that influence its capacity and application range.

- Plate Thickness: The drum’s plate thickness is another key parameter, directly related to the drum’s load-bearing capacity and durability. Thicker drums, in particular, are suitable for high-tonnage, high-performance lifting machinery.

- Other Relevant Dimensions: In addition to diameter, length, and plate thickness, the drum assembly includes other relevant dimensions, such as the helical groove design. Such designs can enhance lifting performance, reduce wear on the wire rope and drum, and extend the service life.

WZL type drum C type drum

| D×L | Drawing No. | Drum coupling | Lifting capacity (t) |

Lifting height (m) | D1 | D2 | D3 | m | P | R | S | H | Reducer |

| Φ400×1000 | TW1022A | WZL05 | 5 | 15 | 409 | 510 | 460 | 48 | 16 | 248 | 16 | 210 | QJYD3-225 |

| TW1028A | QJS-D280 | ||||||||||||

| Φ400×1500 | TW1023A | WZL05 | 5/10 | 22/16 | 409 | 510 | 460 | 150/50 | 16 | 248 | 16 | 210 | QJYD3-225 |

| TW1029A | QJS-D280 | ||||||||||||

| φ500×1500 | TW1024A | WZL06 | 16/20 | 16/12 | 512 | 640 | 580 | 120 | 20 | 316 | 20 | 260 | QJYD3-280 |

| TW1030A | WZL07 | QJRS-D400 | |||||||||||

| φ650×2000 | TW1025A | WZL09 | 32 | 17 | 664 | 810 | 750 | 150 | 24 | 402 | 24 | 360 | QJYD3-400 |

| TW1031A | QJRS-D500 | ||||||||||||

| φ800×2000 | TW1027A | WZL10 | 50 | 12 | 816 | 960 | 900 | 350 | 28 | 478 | 26 | 420 | QJYD3-450 |

| TW1032A | QJRS-D560 | ||||||||||||

| φ800×3600 | TW505A | WZL11 | 75 | 20 | 816 | 950 | 890 | 450 | 34 | 498 | 30 | 420 | QJYD3-500 |

| TW1033A | QJRS-D630 | ||||||||||||

| φ1000×3500 | TW632A | WZL12 | 100/125 | 20 | 1020 | 1200 | 1100 | 300 | 36 | 595 | 34 | 530 | QJYD3-560 |

| TW1034A | QJRS-D710 |

Video

Faq

1. What is a crane drum and how does it work?

A crane drum, also known as a wire rope drum or hoist drum, is a critical component of lifting equipment. It is used to wind and unwind the wire rope, allowing the crane to lift, lower, or move heavy loads efficiently. HL CRANE manufactures crane drums in China with precise machining and heat treatment, ensuring smooth rope winding and long service life. You can find more information at www.hnhlcrane.com.

2. Who are reliable manufacturers of crane drums in China?

China has many crane drum suppliers, but HL CRANE stands out as a professional manufacturer and factory with years of industry experience. The company produces wire rope drums, hoist drums, and other crane spare parts such as wheels, hooks, and pulleys. HL CRANE focuses on steel plate welding technology, advanced machining, and strict quality inspection to deliver durable products. Learn more about crane drum solutions at www.hnhlcrane.com.

3. Can crane drums be customized for different lifting requirements?

Yes, crane drums can be customized to suit various crane types, lifting capacities, and rope diameters. HL CRANE’s factory in China provides OEM and tailored designs, including single-groove, multi-groove, and spiral-groove drums. Whether for overhead cranes, gantry cranes, or hoists, the company ensures compatibility with different working environments, such as foundries, shipyards, and construction sites. Custom solutions help customers improve efficiency and extend equipment life.

4. What materials and treatments are used for high-quality crane drums?

High-quality crane drums are usually made of welded steel plates or high-grade cast steel to withstand heavy loads and wear. At HL CRANE in China, every drum undergoes CNC machining, heat treatment, and balancing to ensure smooth operation and safety. The grooves are precisely cut to match the rope diameter, preventing rope slippage or uneven wear. This guarantees reliability even in heavy-duty applications. More technical details are available on www.hnhlcrane.com.