FEM standard crane hook

FEM standard crane hook parameters:

- Specifications: 3.2t, 5t, 10t, 16t, 20t, 32t, 50t, 75t, 100t, 125t, 160t, 200t, 320t, 400t, 500t

- Working level: M5, M6, M7,

- Hook material: 35CrMo (≤100t), 34Cr2Ni2Mo (>100t)

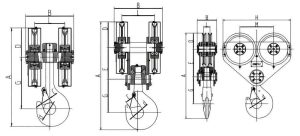

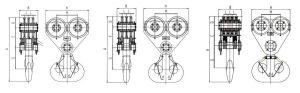

- Hook pulley assembly form: straight pulley, inclined pulley

- Hook type: forged single hook, forged double hook

The FEM Standard Crane Hook is an efficient and safe Crane Hook designed specifically for European-style cranes to improve work efficiency and safety.

Features of the FEM Standard Crane Hook

- Compact Size and Long Service Life: Its efficient and durable design makes it both small in size and long-lasting.

- Lightweight: Compared to traditional hook groups of the same tonnage, it typically weighs about half as much. This lightweight design not only reduces the crane’s load but also enhances its overall performance.

- User-Friendly Design: The design allows for an increased lifting height of the hook, ensuring convenience and safety in use.

- DIN Standard Hook: Equipped with a safety latch and wire rope guard, which enhance operational safety.

- Forged with High-Strength T-Grade Material: Ensures the hook’s strength and durability.

- Non-Destructive Testing Certification Included: Each hook comes with a certificate verifying product quality and safety.

Additionally, the FEM Standard Crane Hook has been ISO 9001 certified for quality and safety, demonstrating its compliance with rigorous quality and environmental management standards. It offers a wide load range, from 1 to 500 tons, catering to various work scenarios.

Composition of the FEM Standard Crane Hook

Hook is composed of various components, including a movable pulley, spacer sleeve, pulley axle, pulley axle clamp, hook yoke plate, rope stopper shaft, hook nut, thrust bearing, hook beam, beam clamp, hook, anti-drop device, shaft end cover, end retaining cover, retaining ring, wire rope stop plate, hook nut positioning plate, connecting frame, and more. These carefully designed and selected parts ensure the efficiency and safety of the hook group.

In summary, the FEM Crane Hook, with its unique design and outstanding performance characteristics, has secured a place in modern industry as a key tool for improving work efficiency and ensuring operational safety.

5t 10t 16t

20t 32t 50t

75t 100t 160t

| Drawing No. | Lifting capacity | Size(mm) | |||||||||

| A | B | E | G | D | L | H | M | C | d | ||

| XG005 | 5t | 650 | 327 | / | 340 | 193 | 202 | / | / | 63 | 80 |

| XG010 | 10t | 1000 | 458 | 295 | 300 | 243 | 310 | / | / | 90 | 112 |

| XG016 | 16t | 1200 | 279 | 390 | 380 | 200 | 87 | 960 | 480 | / | 140 |

| XG020 | 20t | 1290 | 300 | 400 | 430 | 200 | 100 | 960 | 480 | / | 160 |

| XG032 | 32t | 1560 | 365 | 460 | 520 | 250 | 120 | 1198 | 590 | 160 | 200 |

| XG050 | 50t | 1760 | 470 | 500 | 620 | 250 | 180 | 1198 | 590 | 200 | 250 |

| XG075 | 75t | 1783 | 518 | 550 | 600 | 285 | 120 | 1206 | 600 | / | 224 |

| XG125 | 125t | 1935 | 565 | 580 | 678 | 285 | 135 | 1200 | 600 | / | 250 |

| XG160 | 160t | 2050 | 722 | 630 | 691.5 | 285 | 130 | 1200 | 600 | / | 280 |