Drum gear couplings

Parameters for Drum Gear Couplings:

- Maximum Allowable Torque: 0.63 kN·m to 5600 kN·m

- Maximum Rotational Speed: 4000 rpm to 950 rpm

- Coupling Material: ZG430-640, 45 steel

- Coupling Models: GⅡCL, GⅡCLZ

- Custom Options: Non-standard customization is available; you can provide drawings, and we will manufacture according to the specified dimensions.

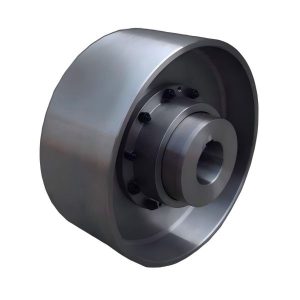

Overview and Functionality

Drum gear couplings are a type of flexible coupling with radial, axial, and angular misalignment compensation capabilities. To achieve this flexibility, the teeth of the outer gear ring are designed with a crowned tooth shape, and the tooth top is shaped as a spherical surface centered on the axis, leaving significant gaps at the top and sides of the teeth. These features allow the coupling to compensate for relative displacement between the two shafts.

Design Features and Connection Method

Additionally, the design of Drum gear couplings enables a variable instantaneous transmission ratio that fluctuates periodically. This is achieved by placing toothed elements made of non-metallic materials into the flange holes of the two coupling halves, connecting them effectively. The coupling can accommodate substantial axial displacement, although its radial and angular misalignment compensation capacities are relatively limited. With a simple structure, ease of manufacturing, and convenient maintenance, Drum gear couplings are widely used in industries such as metallurgy, mining, and lifting and transport equipment.

Advantages and Applications

The advantages of Drum gear couplings include a compact structure, small rotational radius, high load capacity, high transmission efficiency, low noise, and long maintenance intervals. They are suitable for a broad range of operating temperatures, from -20°C to +80°C. The simplified mold forming of the housing reduces manufacturing costs and offers good self-lubricating properties, making Drum gear couplings an ideal approximation to universal flexible couplings. Furthermore, the assembly and maintenance of the couplings are especially straightforward, making them widely used in equipment like hydraulic pumps, lubrication pumps, pneumatic pumps, compressors, and textile machinery.

Specifications and Performance

couplings are available in a diverse range, with 28 specifications and 20 types, featuring bore diameters up to 1200 mm and torque capacities reaching 8,191,813 Nm, highlighting their exceptional load-bearing capacity.

Design Considerations for Enhanced Service Life

Moreover, the design of couplings incorporates critical considerations for enhancing service life. For instance, performance is optimized through refined shaping and flexible elements between the teeth. The tooth width factor affects both the root bending strength and the contact strength of the tooth surface. A larger tooth width requires a greater crown radius and more side clearance. Therefore, these factors must be balanced during design to ensure the performance and durability of the coupling.

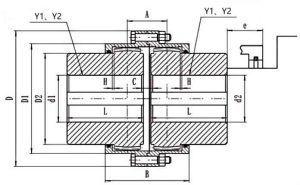

GⅡCL Drum gear couplings basic parameters and main dimensions

| Type | Nominal torque (KN.m) |

Permissible speed (r/min) |

Shaft hole diameter (mm) |

Shaft hole length:L | D | D1 | D2 | C | H | A | B | e | Moment of Inertia (kg/m²) |

Grease quantity (ml) |

weight (kg) |

|

| d1,d2 | Y1 | Y2 | ||||||||||||||

| GⅡCL1 | 0.63 | 6500 | 16,18,19 | 42 | / | 103 | 71 | 50 | 8 | 2 | 36 | 76 | 38 | 0.0016 | 51 | 3.4 |

| 20,22,24 | 52 | 38 | 0.003 | 3.2 | ||||||||||||

| 25,28 | 62 | 44 | 0.0031 | 3.3 | ||||||||||||

| 30,32,35 | 82 | 60 | 0.0032 | 3.5 | ||||||||||||

| GⅡCL2 | 1 | 6000 | 20,22,24 | 52 | / | 115 | 83 | 60 | 8 | 2 | 42 | 88 | 42 | 0.0024 | 70 | 4.6 |

| 25,28 | 62 | 44 | 0.0023 | 4.1 | ||||||||||||

| 30,32,35,38 | 82 | 60 | 0.0024 | 4.5 | ||||||||||||

| 40,42,45 | 112 | 84 | 0.0025 | 4.6 | ||||||||||||

| GⅡCL3 | 1.6 | 5600 | 22,24 | 52 | / | 127 | 95 | 75 | 8 | 2 | 44 | 90 | 42 | 0.0044 | 68 | 6.1 |

| 25,28 | 62 | 44 | 0.0042 | 5.5 | ||||||||||||

| 30,32,35,38 | 82 | 60 | 0.0045 | 6.3 | ||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 0.0101 | 6.9 | ||||||||||||

| GⅡCL4 | 2.8 | 5100 | 38 | 82 | 60 | 49 | 116 | 90 | 8 | 2 | 49 | 98 | 42 | 0.0205 | 87 | 9.5 |

| 40.42.45.48,50,55,56 | 112 | 84 | 0.0228 | 11.3 | ||||||||||||

| 60,63,65 | 142 | 107 | 0.0234 | 10.5 | ||||||||||||

| GⅡCL5 | 4.5 | 4600 | 40,42,45,48,50,55,56 | 112 | 84 | 167 | 134 | 105 | 10 | 2.5 | 55 | 108 | 42 | 0.0418 | 125 | 15.9 |

| 60,63,65,70,71,75 | 142 | 107 | 0.0444 | 16 | ||||||||||||

| GⅡCL6 | 6.3 | 4300 | 45,48,50,55,56 | 112 | 84 | 87 | 153 | 125 | 10 | 2.5 | 56 | 10 | 42 | 0.0706 | 148 | 21.2 |

| 60,63,65,70,71,75 | 142 | 107 | 0.0777 | 23 | ||||||||||||

| 80,85,90 | 172 | 132 | 0.0809 | 22.1 | ||||||||||||

| GⅡCL7 | 8 | 4000 | 50,55,56 | 112 | 84 | 204 | 170 | 140 | 10 | 2.5 | 60 | 118 | 42 | 0.103 | 175 | 27.6 |

| 60,63,65,70,71,75 | 142 | 107 | 0.115 | 33 | ||||||||||||

| 80,85,90,95 | 172 | 132 | 0.1298 | 39.2 | ||||||||||||

| 100,(105) | 212 | 167 | 0.151 | 47.5 | ||||||||||||

| GⅡCL8 | 11.2 | 3700 | 55,56 | 112 | 84 | 230 | 186 | 155 | 12 | 3 | 67 | 142 | 47 | 0.167 | 268 | 35.5 |

| 60.63,65,70,71,75 | 142 | 107 | 0.188 | 42.3 | ||||||||||||

| 80,85,90,96 | 172 | 132 | 0.21 | 49.7 | ||||||||||||

| 100,110. (115) | 212 | 167 | 0.241 | 60.2 | ||||||||||||

| GⅡCL9 | 18 | 3350 | 60,63,65,70,71,75 | 142 | 107 | 256 | 212 | 180 | 12 | 3 | 69 | 46 | 47 | 0.316 | 310 | 55.6 |

| 80,85,90,95 | 172 | 132 | 0.356 | 65.6 | ||||||||||||

| 100.110,120,125. | 212 | 167 | 0.413 | 79.6 | ||||||||||||

| 130,(135) | 252 | 202 | 0.47 | 95.8 | ||||||||||||

| GⅡCL10 | 25 | 3000 | 65,70,71,75 | 142 | 107 | 287 | 239 | 200 | 14 | 3.5 | 78 | 164 | 47 | 0.511 | 472 | 72 |

| 80,85,90,95 | 172 | 132 | 0.573 | 84.4 | ||||||||||||

| 100.110.120.125 | 212 | 167 | 0.659 | 101 | ||||||||||||

| 130,140,150 | 252 | 202 | 0.745 | 119 | ||||||||||||

| GⅡCL11 | 35.5 | 2700 | 70,71,75 | 142 | 107 | 325 | 276 | 235 | 14 | 3.5 | 81 | 170 | 47 | 1.454 | 550 | 97 |

| 80,85,90,95 | 172 | 132 | 1.096 | 114 | ||||||||||||

| 100,110,120,125 | 212 | 167 | 1.235 | 138 | ||||||||||||

| 130,140,150 | 252 | 202 | 1.34 | 161 | ||||||||||||

| 160,170,(175) | 302 | 242 | 1.588 | 189 | ||||||||||||

| GⅡCL12 | 56 | 2450 | 75 | 142 | 107 | 362 | 313 | 270 | 16 | 4 | 89 | 190 | 49 | 1.623 | 695 | 128 |

| 80,85,90,95 | 172 | 32 | 1.828 | 150 | ||||||||||||

| 100,110,120,125 | 212 | 167 | 2.113 | 205 | ||||||||||||

| 130,140,150 | 252 | 202 | 2.4 | 213 | ||||||||||||

| 160,170,180 | 302 | 242 | 2.728 | 248 | ||||||||||||

| 190,200 | 352 | 282 | 3.055 | 285 | ||||||||||||

| GⅡCL13 | 80 | 2200 | 150 | 252 | 202 | 412 | 350 | 300 | 18 | 4.5 | 98 | 208 | 49 | 3.951 | 1019 | 222 |

| 160,170,180. (185) | 302 | 242 | 4.363 | 246 | ||||||||||||

| 190,200,220,(225) | 352 | 282 | 4.541 | 242 | ||||||||||||

| GⅡCL14 | 125 | 2000 | 170,180. (185) | 302 | 242 | 462 | 420 | 335 | 22 | 5.5 | 172 | 296 | 63 | 8.025 | 2900 | 421 |

| 190,200,220 | 352 | 282 | 8.8 | 476 | ||||||||||||

| 240,250 | 410 | 330 | 9.275 | 544 | ||||||||||||

| GⅡCL15 | 180 | 1800 | 190,200,220 | 352 | 282 | 512 | 470 | 380 | 22 | 5.5 | 182 | 316 | 63 | 14.3 | 3700 | 608 |

| 240,250,260 | 410 | 330 | 15.85 | 696 | ||||||||||||

| 280,(285) | 470 | 380 | 17.45 | 786 | ||||||||||||

| GⅡCL16 | 250 | 1600 | 220 | 352 | 282 | 580 | 522 | 430 | 28 | 7 | 209 | 354 | 67 | 23.925 | 4500 | 799 |

| 240,250,260 | 410 | 330 | 26.45 | 913 | ||||||||||||

| 280,300,320 | 470 | 380 | 29.1 | 1027 | ||||||||||||

| GⅡCL17 | 355 | 1400 | 250,260 | 410 | 330 | 644 | 582 | 490 | 28 | 7 | 198 | 364 | 67 | 43.095 | 4900 | 1176 |

| 280,(295),300,320 | 470 | 380 | 47.525 | 1322 | ||||||||||||

| 340.360. (365) | 550 | 450 | 53.725 | 1352 | ||||||||||||

| GⅡCL18 | 500 | 1210 | 280,(295),300.320 | 470 | 380 | 726 | 658 | 540 | 28 | 8 | 222 | 430 | 75 | 78.525 | 7000 | 1698 |

| 340,360,380 | 550 | 450 | 87.75 | 1948 | ||||||||||||

| 400 | 650 | 540 | 99.5 | 2278 | ||||||||||||

| GⅡCL19 | 710 | 1050 | 340,320 | 470 | 380 | 818 | 748 | 630 | 32 | 8 | 232 | 440 | 75 | 36.75 | 8900 | 2249 |

| 300,(350),360,380,(390) | 550 | 450 | 153.75 | 2591 | ||||||||||||

| 400,420,440,450,460,(470) | 650 | 540 | 75.5 | 3026 | ||||||||||||

| GⅡCL20 | 1000 | 910 | 360,380. (390) | 550 | 450 | 928 | 838 | 720 | 32 | 10.5 | 247 | 470 | 75 | 261.75 | 11000 | 3384 |

| 400,420,440,450.460.480,500 | 650 | 540 | 299 | 3984 | ||||||||||||

| 530,(540) | 800 | 680 | 360.75 | 4430 | ||||||||||||

| GⅡCL21 | 1400 | 800 | 400,420,440,450.460.480,500 | 650 | 540 | 1022 | 928 | 810 | 40 | 11.5 | 255 | 490 | 75 | 461.6 | 13000 | 3912 |

| 530.560,600 | 800 | 680 | 449.4 | 3754 | ||||||||||||

| GⅡCL22 | 1800 | 700 | 450.460.480,500 | 650 | 540 | 1134 | 1036 | 915 | 40 | 13 | 265 | 510 | 75 | 734.3 | 16000 | 4970 |

| 630,560,600,630 | 800 | 680 | 837 | 5408 | ||||||||||||

| 670,(680) | / | 780 | 785.4 | 4478 | ||||||||||||

| GⅡCL23 | 2500 | 610 | 530.560,600.630 | 800 | 680 | 1282 | 1178 | 1030 | 50 | 14.5 | 299 | 580 | 80 | 1517 | 28000 | 10013 |

| 670,(700)710,750,(770) | / | 780 | 1725 | 11553 | ||||||||||||

| GⅡCL24 | 3550 | 500 | 560,600,630 | 800 | 680 | 1428 | 1322 | 1175 | 50 | 16.5 | 317 | 610 | 80 | 2486 | 33000 | 12915 |

| 670,(700),710.750 | / | 780 | 2838.5 | 15015 | ||||||||||||

| 800,850 | / | 880 | 3131.75 | 16615 | ||||||||||||

| GⅡCL25 | 5600 | 420 | 670,(700),710.750 | / | 780 | 1664 | 1538 | 1390 | 50 | 19 | 325 | 620 | 80 | 5082 | 43000 | 15760 |

| 800,850 | / | 880 | 5344 | 15515 | ||||||||||||

| 900,950 | / | 980 | 5484 | 15054 | ||||||||||||

| 1000,(1040) | / | 1100 | 5615 | 14513 | ||||||||||||

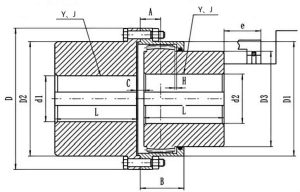

GⅡCLZ Drum gear couplings basic parameters and main dimensions

| Type | Nominal torque (KN.m) |

Permissible speed (r/min) |

Shaft hole diameter (mm) |

Shaft hole length:L | D | D2 | D1 | D3 | C | H | A | B | e | Moment of Inertia (kg/m²) |

Grease quantity (ml) |

weight (kg) |

|

| d1,d2 | Y | J | |||||||||||||||

| GⅡCLZ1 | 0.63 | 6500 | 16,18,19 | 42 | / | 103 | 71 | 71 | 50 | 8 | 2 | 18 | 38 | 38 | 0.004 | 31 | 3.5 |

| 20,22,24 | 52 | 38 | 0.0375 | 3.3 | |||||||||||||

| 25,28 | 62 | 44 | 0.004 | 3.5 | |||||||||||||

| 30,32,35,38* | 82 | 60 | 0.005 | 4.1 | |||||||||||||

| 40*,42*,45*,48*,50* | 112 | 84 | 0.007 | 5.7 | |||||||||||||

| GⅡCLZ2 | 1 | 6000 | 20.22,24 | 52 | / | 115 | 83 | 83 | 60 | 8 | 2 | 2 | 44 | 42 | 0.00675 | 42 | 5.3 |

| 25.28 | 62 | 44 | 0.00625 | 4.8 | |||||||||||||

| 30,32,35,38 | 82 | 60 | 0.007 | 5.7 | |||||||||||||

| 40,42,45,48*,50*,55*,56* | 112 | 84 | 0.008 | 7.2 | |||||||||||||

| 60* | 142 | 107 | 0.01 | 9.2 | |||||||||||||

| GⅡCLZ3 | 1.6 | 5600 | 22,24 | 52 | / | 127 | 95 | 95 | 75 | 8 | 2 | 22 | 45 | 42 | 0.009 | 42 | 3.8 |

| 25,28 | 62 | 44 | 0.011 | 7.8 | |||||||||||||

| 30,32,35,38 | 82 | 60 | 0.011 | 7.6 | |||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 0.01325 | 9.8 | |||||||||||||

| 60*,63*,65*,70 | 142 | 107 | 0.01675 | 12.5 | |||||||||||||

| GⅡCLZ4 | 2.8 | 5100 | 38 | 82 | 60 | 149 | 116 | 116 | 90 | 8 | 2 | 24.5 | 49 | 42 | 0.02125 | 53 | 10.5 |

| 40,42,45,48,50,55,56 | 112 | 84 | 0.0255 | 13.5 | |||||||||||||

| 60,63,65,70*,75* | 142 | 107 | 0.039 | 16.5 | |||||||||||||

| 80* | 172 | 132 | 0.04875 | 19.4 | |||||||||||||

| GⅡCLZ5 | 4.5 | 4600 | 40,42,45,48,50,55,56 | 112 | 84 | 169 | 134 | 134 | 105 | 10 | 2.5 | 27.5 | 54 | 42 | 0.044 | 77 | 18.1 |

| 60,63,65,70,71,75 | 142 | 107 | 0.05175 | 23.1 | |||||||||||||

| 80°,85*,90* | 172 | 132 | 0.0625 | 28.5 | |||||||||||||

| GⅡCLZ6 | 6.3 | 4300 | 45,48,50,55,56 | 112 | 84 | 187 | 153 | 153 | 125 | 10 | 2.5 | 28 | 55 | 42 | 0.075 | 91 | 23.9 |

| 60,63,65,70,71,75 | 142 | 107 | 0.089 | 29.3 | |||||||||||||

| 80,85,90,95* | 172 | 132 | 0.10425 | 35.4 | |||||||||||||

| 100*,(105)* | 212 | 167 | 0.1065 | 36.2 | |||||||||||||

| GⅡCLZ7 | 8 | 4000 | 50,55,56 | 112 | 84 | 204 | 170 | 170 | 140 | 10 | 2.5 | 30 | 59 | 42 | 0.1145 | 108 | 29.6 |

| 60,63,65,70,71,75 | 142 | 107 | 0.1335 | 36.3 | |||||||||||||

| 80,85,90,95 | 172 | 132 | 0.157 | 43.8 | |||||||||||||

| 100,(105),110*,(105*) | 212 | 167 | 0.1898 | 54.3 | |||||||||||||

| GⅡCLZ8 | 11.2 | 3700 | 55,56 | 112 | 84 | 230 | 186 | 186 | 155 | 12 | 3 | 33.5 | 71 | 47 | 0.184 | 161 | 37.8 |

| 60,63,65,70,71,75 | 142 | 107 | 0.215 | 46.1 | |||||||||||||

| 80,85,90,95 | 172 | 132 | 0.249 | 54.9 | |||||||||||||

| 100,110,(115),120*,125* | 212 | 167 | 0.297 | 67.4 | |||||||||||||

| GⅡCLZ9 | 18 | 3350 | 60,63,65,70,71,75 | 142 | 107 | 256 | 212 | 212 | 180 | 12 | 3 | 34.5 | 73 | 47 | 0.358 | 184 | 60 |

| 80,85,90,95 | 172 | 132 | 0.415 | 71.8 | |||||||||||||

| 100,110,120,125 | 212 | 167 | 0.499 | 88 | |||||||||||||

| 130,(135),140*,150* | 252 | 202 | 0.575 | 104.4 | |||||||||||||

| GⅡCLZ10 | 25 | 3000 | 55,70,71,75 | 142 | 107 | 287 | 239 | 239 | 200 | 14 | 3.5 | 39 | 82 | 47 | 0.58 | 276 | 76.1 |

| 80,85,90,95 | 172 | 132 | 0.6728 | 91.1 | |||||||||||||

| 100,110,120,125 | 212 | 167 | 0.8025 | 111.5 | |||||||||||||

| 130,140,150 | 252 | 202 | 0.935 | 133.5 | |||||||||||||

| GⅡCLZ11 | 35.5 | 2700 | 110,120,125 | 212 | 167 | 325 | 276 | 250 | 235 | 14 | 3.5 | 40.5 | 85 | 47 | 1.223 | 322 | 137 |

| 130,140,150 | 252 | 202 | 1.41 | 162.4 | |||||||||||||

| 160,170,(175) | 302 | 242 | 1.625 | 193 | |||||||||||||

| GⅡCLZ12 | 56 | 2450 | 130,140,150 | 252 | 202 | 360 | 313 | 286 | 270 | 16 | 4 | 44.5 | 95 | 49 | 2.39 | 404 | 212.8 |

| 160,170,180 | 302 | 242 | 2.763 | 268 | |||||||||||||

| 190,200 | 352 | 285 | 3.093 | 290 | |||||||||||||

| GⅡCLZ13 | 80 | 2200 | 150 | 252 | 202 | 412 | 350 | 322 | 300 | 18 | 4.5 | 49 | 104 | 49 | 3.93 | 585 | 272.3 |

| 160,170,180,(185) | 302 | 242 | 4.535 | 320 | |||||||||||||

| 190,200,220,(225) | 352 | 282 | 6.34 | 370 | |||||||||||||

| GⅡCLZ14 | 125 | 2000 | 170,180,(185) | 302 | 242 | 462 | 420 | 335 | / | 22 | 5.5 | 86 | 148 | 63 | 6.9 | 1600 | 389 |

| 190,200,220 | 352 | 282 | 7.675 | 438 | |||||||||||||

| 240,250 | 410 | 330 | 8.6 | 509 | |||||||||||||

| GⅡCLZ15 | 180 | 1800 | 190,200,220 | 352 | 282 | 512 | 465 | 380 | / | 22 | 5.5 | 91 | 158 | 63 | 2.425 | 2100 | 566 |

| 240,250,260 | 410 | 330 | 13.975 | 650 | |||||||||||||

| 280,(285) | 470 | 380 | 15.575 | 740 | |||||||||||||

| GⅡCLZ16 | 250 | 1600 | 220 | 352 | 282 | 580 | 522 | 430 | / | 28 | 7 | 104.5 | 177 | 67 | 21.2 | 2500 | 751 |

| 240,250,260 | 410 | 330 | 23.125 | 857 | |||||||||||||

| 280,300,320 | 470 | 380 | 26.35 | 974 | |||||||||||||

| GⅡCLZ17 | 355 | 1400 | 250,260 | 410 | 330 | 644 | 582 | 490 | / | 28 | 7 | 99 | 182 | 67 | 38.825 | 2700 | 1110 |

| 280,(290),300,320 | 470 | 380 | 43.25 | 1255 | |||||||||||||

| 340,360,(365) | 550 | 450 | 49.5 | 1465 | |||||||||||||

| GⅡCLZ18 | 500 | 1210 | 280,(295),300,320 | 470 | 380 | 726 | 658 | 540 | / | 28 | 8 | 111 | 215 | 75 | 69.5 | 3900 | 1580 |

| 340,360,380 | 550 | 450 | 78.75 | 1830 | |||||||||||||

| 400 | 560 | 540 | 90.5 | 2160 | |||||||||||||

| GⅡCLZ19 | 710 | 1050 | 300,320 | 470 | 380 | 818 | 748 | 630 | / | 32 | 9 | 116 | 220 | 75 | 122.5 | 5000 | 2115 |

| 340,(350),360,380,(390) | 550 | 450 | 139.5 | 2457 | |||||||||||||

| 400,420,440,450,460,(470) | 650 | 540 | 161.25 | 2892 | |||||||||||||

| GⅡCLZ20 | 1000 | 910 | 360,380,(390) | 550 | 450 | 928 | 838 | 720 | / | 32 | 10.5 | 123.5 | 235 | 75 | 240 | 6200 | 3223 |

| 400,420,440,450,460,480,(500) | 650 | 540 | 277.25 | 3793 | |||||||||||||

| 530,(540) | 800 | 680 | 335 | 4680 | |||||||||||||

| GⅡCLZ21 | 1400 | 800 | 400.420.440.450.460.480.500 | 650 | 540 | 1022 | 928 | 810 | / | 40 | 11.5 | 127.5 | 245 | 75 | 435 | 7000 | 4780 |

| 530,560,600 | 800 | 680 | 527.75 | 5905 | |||||||||||||

| GⅡCLZ22 | 1800 | 700 | 450,460,480,500 | 650 | 540 | 1134 | 1036 | 915 | / | 40 | 13 | 131.1 | 255 | 75 | 701.25 | 8700 | 6069 |

| 530.560.600.630 | 800 | 680 | 852.25 | 7504 | |||||||||||||

| 670. (680) | 900 | 780 | |||||||||||||||

| GⅡCLZ23 | 2500 | 610 | 530,560,600,630 | 800 | 680 | 1282 | 1178 | 1030 | / | 50 | 14.5 | 149.5 | 290 | 80 | 415.75 | 15000 | 9633 |

| 670,(700),710,750,(770) | 900 | 780 | 638.75 | 11133 | |||||||||||||

| GⅡCLZ24 | 3550 | 500 | 560,600,630 | 800 | 680 | 1428 | 1322 | 1175 | / | 50 | 16.5 | 158.5 | 305 | 80 | 2330.5 | 18000 | 12460 |

| 670,710,750 | 900 | 780 | 2682.75 | 14465 | |||||||||||||

| 800,850 | 1000 | 880 | 2976.25 | 16110 | |||||||||||||

| GⅡCLZ25 | 5600 | 420 | 670, (700),710,750 | 900 | 780 | 1644 | 1538 | 1390 | / | 50 | 19 | 162.5 | 310 | 80 | 5174.25 | 23000 | 19837 |

| 800,850 | 1000 | 880 | 5836.5 | 22381 | |||||||||||||

| 900,950 | / | 980 | 6413 | 24765 | |||||||||||||

| 1000,(1040) | / | 1100 | 7198.25 | 27797 | |||||||||||||