Crane safety brakes

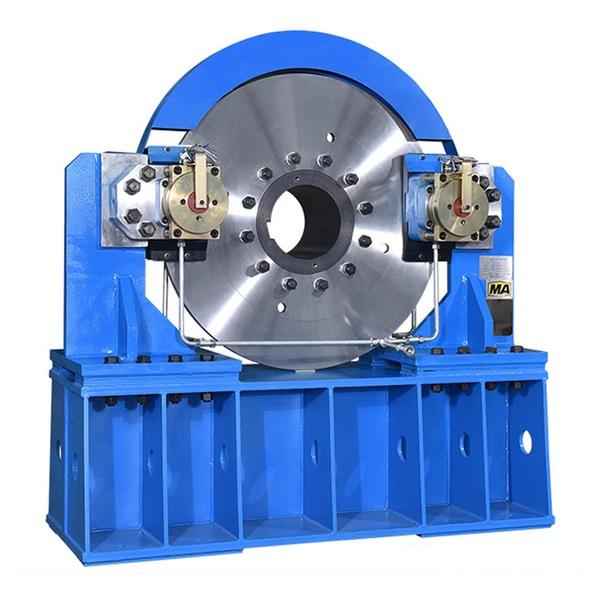

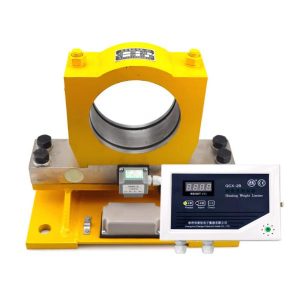

SB Series Crane Safety Brakes:

- Product Models: SB50, SB100, SB160, SB250, SB315, SB400, SB500

- Applicable Disc Diameter (mm): 500, 600, 1200, 1800

- Brake Disc Thickness (mm): 30, 36, 40

- Clamping Force F (KN): 50–500

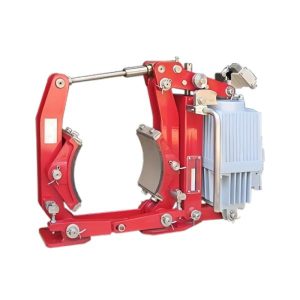

Hydraulic Safety Emergency Brakes

The SB series crane safety brakes are high-power braking devices designed for low-speed shafts (drum shafts). These brakes are widely suitable for emergency safety braking on medium and large cranes, port handling machinery lifts, and boom tilting mechanism low-speed shafts. They are also ideal for the operational and emergency safety braking of mining hoists, lift equipment, and high-power inclined belt conveyors, as well as for safety braking in cable car and cable crane drive mechanisms. Additionally, they provide emergency braking for the low-speed shafts of hoist mechanisms in special lifting applications, such as casting cranes.

Main Features of Crane Safety Brakes

- Featuring a normally closed design, these brakes are safe and reliable. The braking force is applied by a specially designed disc spring, while hydraulic power releases the brake (see the hydraulic station catalog for hydraulic station selection).

- Equipped with high-performance, asbestos-free hard friction pads, they offer a stable friction coefficient without damaging the brake disc and are resistant to water and salt fog (sea spray).

- The brakes are highly responsive, with short closing (braking) times.

- Optional switches, such as release limit and pad wear limit, are available for signal display or interlock protection.

- A well-designed sealing structure and premium imported seals provide effective sealing and long service life.

- Flexible installation options make the brakes easy to use, adjust, and maintain.

Operating Conditions for Crane Safety Brakes

- Ambient temperature: -20°C to +50°C

- Relative humidity: ≤90%

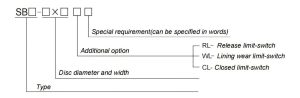

Order Mark

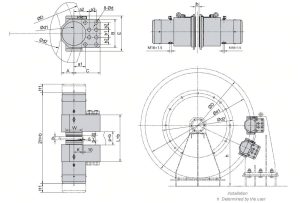

Dimensions and technical data

Technical data of SB series safety brakes |

|||||||||||||||||||||

| Type | Clamp force F (KN) |

Release pressure (MPa) |

Releaseoil volume (ml) |

Clearance (mm) |

Friction coefficient | Mounting bolts bolts/performance class/Installation torque |

Weight bracket excluded (kg) |

||||||||||||||

| Static | Dynamic | ||||||||||||||||||||

| SB50 | 50 | 1 | 30 | 1-2 | 0.4 | 0.36 | 8-M20、10.9、550±10 | 90 | |||||||||||||

| SB100 | 100 | 12 | 50 | 1-2 | 0.4 | 0.36 | 8-M24、10.9、950±10 | 150 | |||||||||||||

| SB160 | 160 | 12 | 70 | 1-2 | 0.4 | 0.36 | 8-M30、10.9、1900±20 | 310 | |||||||||||||

| SB250 | 250 | 16.5 | 95 | 1-2 | 0.4 | 0.36 | 8-M36、10.9、3300±40 | 452 | |||||||||||||

| SB315 | 315 | 17 | 115 | 1-2 | 0.4 | 0.36 | 8-M36、10.9、3300±40 | 672 | |||||||||||||

| SB400 | 400 | 16.5 | 170 | 1-2 | 0.4 | 0.36 | 8-M48、10.9、7500±100 | 1100 | |||||||||||||

Brake torque Nm=F×μ×d1 |

|||||||||||||||||||||

| Type | A | a1 | a2 | a3 | b1 | b2 | B | C | d | k | P | L | E | W | H | H1 | |||||

| SB50 | 77 | 77 | 90 | 38 | 38 | 38 | 154 | 150 | 20.5 | 56 | 102 | 300 | 240 | 110 | 310 | 80 | |||||

| SB100 | 95 | 95 | 105 | 45 | 55 | 45 | 190 | 180 | 25 | 71 | 102 | 348 | 286 | 140 | 360 | 85 | |||||

| SB160 | 110 | 120 | 135 | 65 | 70 | 65 | 260 | 235 | 31 | 87 | 106 | 412 | 370 | 170 | 410 | 95 | |||||

| SB250 | 130 | 120 | 160 | 75 | 80 | 75 | 300 | 275 | 37 | 87 | 106 | 456 | 370 | 170 | 470 | 110 | |||||

| SB315 | 140 | 175 | 205 | 85 | 90 | 82.5 | 335 | 330 | 37 | 137 | 106 | 476 | 410 | 270 | 500 | 110 | |||||

| SB400 | 170 | 180 | 220 | 120 | 110 | 110 | 440 | 420 | 50 | 137 | 142 | 602 | 546 | 270 | 560 | 115 | |||||

| SB500 | 170 | 180 | 220 | 120 | 110 | 110 | 440 | 420 | 50 | 137 | 142 | 682 | 542 | 270 | 600 | 115 | |||||

Relative Dimensions of brake disc(mm) |

|||||||||||||||||||||

| Type | b | D | d1 | d2 max | |||||||||||||||||

| SB50 | 30 | 36 | 40 | ≥500 | D-120 | D-300 | |||||||||||||||

| SB100 | 30 | 36 | 40 | ≥500 | D-150 | D-380 | |||||||||||||||

| SB160 | 30 | 36 | 40 | ≥600 | D-180 | D-440 | |||||||||||||||

| SB250 | 30 | 36 | 40 | ≥600 | D-180 | D-480 | |||||||||||||||

| SB315 | 30 | 36 | 40 | ≥1200 | D-280 | D-600 | |||||||||||||||

| SB400 | 30 | 36 | 40 | ≥1800 | D-280 | D-660 | |||||||||||||||

| SB500 | 30 | 36 | 40 | ≥1800 | D-280 | D-660 | |||||||||||||||

| d1=the theoretical friction diameter, d2=max .allowable drum or hub diameter D:For other disc diameters please contact us |

|||||||||||||||||||||