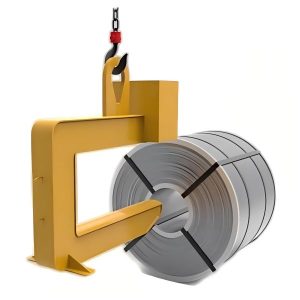

Crane grab

Singlr rope grab,Four rope grab,Electro-hydraulic multi-flap grab,Orange peel grab,Electric motor grab,Electro-Hydraulicclamshell grab

Crane Grab Overview

A crane grab is a specially designed lifting device used with cranes for handling and transporting bulk materials. It consists of two or more bucket-like jaws that can open and close, operated by the hoisting and opening/closing mechanisms of the crane to grab and release materials. This device offers high operational efficiency and is widely used for handling bulk cargo in ports, mines, factories, and other similar settings.

Safety Guidelines for Using Crane Grabs

When operating a crane grab, it is essential to follow these safety practices:

- The crane must be operated by a certified crane operator.

- Do not allow anyone to remain on the crane during operation.

- When carrying heavy loads, maintain a clearance of at least 0.5 meters above any obstruction along the load’s path.

- Ensure that the hoisting rope and closing rope maintain equal speeds when lifting the grab.

- Avoid using the grab to lift solid objects in one piece.

- Inspect the tightness of suspension ropes and the condition of pulley wheels for the closing ropes before each shift.

Types of Crane Grabs and Their Features

Single-Rope Grab

- Mechanism: Operates with one wire rope to perform both lifting and opening/closing actions, utilizing a special locking mechanism.

- Features: Suitable for cranes with a single lifting drum (single-hook), allowing seamless opening and closing during loading and unloading. Easy to attach and detach, making it suitable for underwater and land-based operations such as grabbing and stacking.

- Limitations: Cannot open in mid-air, except for hand-pull or remote-controlled types.

Double-Rope Grab

- Mechanism: Designed for cranes with dual lifting mechanisms (single rope for each drum). It uses one rope for balance and the other for opening and closing the grab.

- Features:

- Often used in ports, docks, and construction industries.

- Available in light, medium, heavy, and ultra-heavy configurations based on material properties.

- Designed for handling loose, bulk materials.

Four-Rope Grab

- Mechanism: Used with cranes equipped with two sets of wire rope drums. It employs two ropes for support and two for opening and closing the jaws.

- Applications: Suitable for tasks like loading, unloading, stacking, and feeding materials. Often used with bridge or gantry cranes.

- Customization: Can be tailored with teeth, parallel beams, or for underwater operations based on user needs and material characteristics.

Multi-Claw Grab

- Applications: Efficiently handles scrap metal, large solid materials, and waste in challenging environments such as ports, railways, metallurgy, and construction.

- Features:

- Available in single-rope, double-rope, four-rope, and electric models.

- The jaws close individually based on material size and shape, ensuring effective handling.

- Designed with 4 to 8 jaws, customizable based on user requirements and material properties.

Log Grab

- Applications: Specifically designed for handling timber in lumberyards, large woodworking factories, paper mills, and ports. Used for unloading ships, stacking logs, and other related tasks.

- Features:

- Available in single-rope, double-rope, four-rope, and electric models.

- Customizable to meet specific user needs.

Motorized Grab

- Mechanism: Equipped with its own opening/closing mechanism, allowing operation at any height for handling materials.

- Features:

- Higher productivity compared to single-rope grabs.

- Easy attachment and detachment with high loading/unloading efficiency.

- Suitable for handling loose bulk materials.

- Requires an energy supply cable reel for higher lifting heights.

- Limitation: Not suitable for underwater operations.

Electric Hydraulic Multi-Claw Grab

- Applications: Designed for handling irregular and large materials like scrap steel, pig iron, ore, and waste in harsh environments, effectively replacing manual labor.

- Features:

- Equipped with an independent hydraulic system, using high-quality components for excellent performance.

- Each jaw is driven by a separate hydraulic cylinder, ensuring no material spillage.

- Includes a cable connector on the top for easy crane integration.

- Available in multiple configurations: circular or rectangular jaws, and closed, semi-open, or open claw designs.