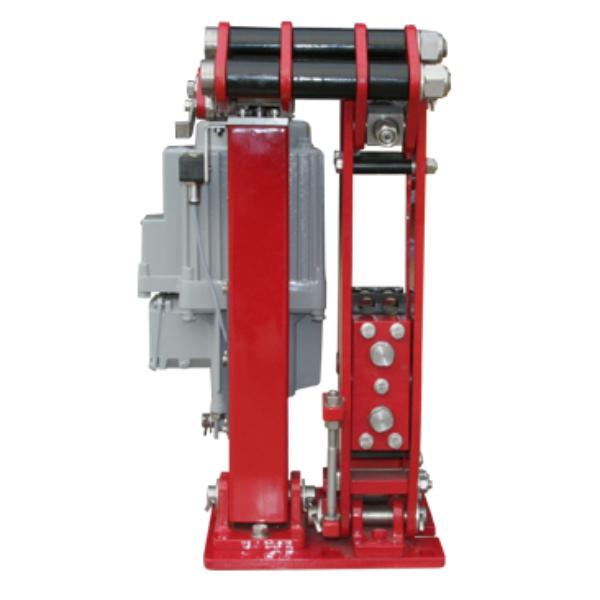

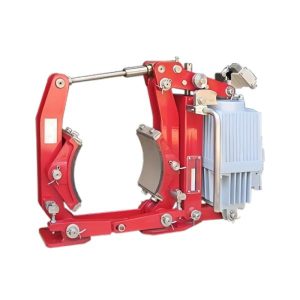

Crane disc brakes

YP1 Series Crane Disc Brakes

- Actuator model: Ed220-50, Ed300-50, Ed500-60, Ed800-60

- Brake disc diameter (mm): 315–500

- Maximum braking torque (N.m): 280–1750

YP2 Series Crane Disc Brakes

- Actuator model: Ed500-60, Ed800-60, Ed1250-60, Ed2000-60, Ed3000-60

- Brake disc diameter (mm): 450–710

- Maximum braking torque (N.m): 1000–8400

YP3 Series Crane Disc Brakes

- Actuator model: Ed1250-80, Ed2000-80, Ed1250-60, Ed3000-80

- Brake disc diameter (mm): 630–1250

- Maximum braking torque (N.m): 3750–20000

Electric Hydraulic Disc Brakes

The YP1, YP2, and YP3 series crane disc brakes are high-performance, multifunctional, and advanced products. With features such as automatic equalization of pad retraction distance and automatic compensation for pad wear, they ensure convenient maintenance during use. Additionally, various limit switches can be installed to provide essential interlock protection signals to the main PLC, making these brakes ideal for deceleration and parking (holding) functions across a range of modern, large-scale equipment, such as specialized handling machinery, lifting and transport machinery, metallurgical equipment, mining equipment, and engineering machinery.

Main Features of Crane Disc Brakes

- Equipped with an interlocking retraction equalization device and an automatic pad positioning system, the brakes maintain equal retraction distances on both sides without adjustment, completely preventing pad contact with the brake disc.

- All main pivot points have self-lubricating bearings, eliminating the need for lubrication; these brakes are efficient, responsive, and close (apply brakes) within 0.25–0.4 seconds.

- The stepless automatic pad wear compensation mechanism maintains consistent retraction distance and braking torque, eliminating the need for frequent adjustments.

- Adjustable internal spring torque, equipped with a torque scale.

- Insert-type brake pads allow for easy replacement and are available in semi-metallic, powder metallurgy, and other materials to suit different operating conditions.

- Paired with a newly designed, highly responsive, and durable actuator.

- Equipped with a manual release device to allow brake release in case of a power outage.

Operating Conditions for Crane Disc Brakes

- Ambient temperature: -20°C to +50°C

- Relative humidity: ≤90%

Optional Accessories for Crane Disc Brakes

- Manual release device

- Release (brake opening) limit switch for indicating proper brake release or providing interlock protection.

- Pad wear limit switch for signaling or providing interlock protection when pads reach their wear limit.

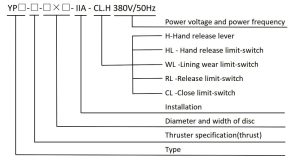

Order Information

Dimensions and technical data of Crane Disc Brakes

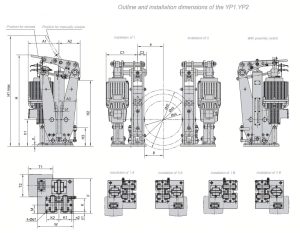

Dimensions and technical data of YP1 series disc brakes |

||||||||||||||||||||||||||||

| Thruster type | h1 | H | H1 | H2 | H3 | b | k | k1 | k2 | d1 | n | n1 | n2 | F | W | M | A1 | A2 | A3 | C1 | C2 | T1 | T2 | |||||

| A | B | A | B | A | B | A | B | |||||||||||||||||||||

| Ed220-50 | 230 | 685 | 845 | 526 | 218 | 70 | 120 | 80 | 180 | 18 | 14 | 20 | 20 | 300 | 300 | 80 | 260 | 250 | 180 | 150 | 245 | 280 | 80 | 197 | 160 | 160 | 197 | |

| Ed300-50 | ||||||||||||||||||||||||||||

| Ed500-60 | 300 | 250 | 260 | 320 | 254 | 194 | 194 | 254 | ||||||||||||||||||||

| Ed800-60 | ||||||||||||||||||||||||||||

| Relative Dimensions of brake disc | Technical data(mm) | |||||||||||||||||||||||||||

| d2 Disc diameter |

b1 | s | d3 | d4 | e | p | Thruster | Disc Diameter | Weight (kg) |

|||||||||||||||||||

| Thruster type | Power (W) |

Rated Current(A) |

Weight (kg) |

315 | 355 | 400 | 450 | 500 | ||||||||||||||||||||

| 315 | 20 | 0.7~0.9 | 235 | 120 | 117.5 | 58 | Max.Brake torque μ=0.4 | |||||||||||||||||||||

| 355 | 20 | 275 | 160 | 137.5 | 78 | Ed220-50 | 120 | 0.38 | 10 | 280 | 320 | 85 | ||||||||||||||||

| 400 | 20 | 320 | 205 | 160 | 100 | Ed300-50 | 250 | 0.78 | 14 | 400 | 450 | 500 | 88 | |||||||||||||||

| 450 | 20 | 370 | 255 | 185 | 125 | Ed500-60 | 370 | 1.34 | 23 | 710 | 800 | 900 | 1000 | 94 | ||||||||||||||

| 500 | 20 | 420 | 305 | 210 | 150 | Ed800-60 | 550 | 1.52 | 25 | 1150 | 1350 | 1560 | 1750 | 96 | ||||||||||||||

Dimensions and technical data of YP2 series disc brakes |

|||||||||||||||||||||||||||||||||

| Thruster type | h1 | H | H1 | H2 | H3 | b | k | k1 | k2 | d1 | n | n1 | n2 | F | W | M | A1 | A2 | A3 | C1 | C2 | T1 | T2 | ||||||||||

| A | B | A | B | A | B | A | B | ||||||||||||||||||||||||||

| Ed500-60 | 280 | 965 | 1170 | 695 | 195 | 90 | 140 | 130 | 130 | 22 | 15 | 20 | 20 | 370 | 375 | 90 | 335 | 295 | 235 | 190 | 305 | 365 | 92 | 254 | 194 | 194 | 254 | ||||||

| Ed800-60 | |||||||||||||||||||||||||||||||||

| Ed1250-60 | 335 | 310 | 325 | 355 | 268 | 240 | 240 | 268 | |||||||||||||||||||||||||

| Ed2000-60 | |||||||||||||||||||||||||||||||||

| Ed3000-60 | |||||||||||||||||||||||||||||||||

| Relative Dimensions of brake disc | Thechnical data(mm) | ||||||||||||||||||||||||||||||||

| d2 Disc diameter |

b1 | s | d3 | d4 | e | p | Thruster | Disc Diameter | Weight (kg) |

||||||||||||||||||||||||

| Thruster type | Power (W) |

Rated Current(A) |

Weight (kg) |

450 | 500 | 560 | 630 | 710 | |||||||||||||||||||||||||

| 450 | 30 | 0.7~1.1 | 350 | 200 | 175 | 105 | Max.Brake torque μ=0.4 | ||||||||||||||||||||||||||

| 500 | 30 | 400 | 250 | 200 | 130 | Ed500-60 | 370 | 1.34 | 23 | 1000 | 1150 | 1350 | 166 | ||||||||||||||||||||

| 560 | 30 | 460 | 310 | 230 | 160 | Ed800-60 | 550 | 1.52 | 25 | 1600 | 1800 | 2120 | 2500 | 169 | |||||||||||||||||||

| 630 | 30 | 530 | 380 | 265 | 195 | Ed1250-60 | 550 | 1.52 | 40 | 2500 | 2875 | 3350 | 4000 | 4500 | 185 | ||||||||||||||||||

| 710 | 30 | 610 | 460 | 305 | 235 | Ed2000-60 | 750 | 1.98 | 40 | 4000 | 4500 | 5400 | 6300 | 7100 | 189 | ||||||||||||||||||

| Ed3000-60 | 900 | 2.21 | 42 | 4600 | 5300 | 6300 | 7300 | 8400 | 192 | ||||||||||||||||||||||||

| Note:1)s=Brake clearance.2)d4=Max.allowable coupling or hub diameter.3)Average friction factor of standard friction materials | |||||||||||||||||||||||||||||||||

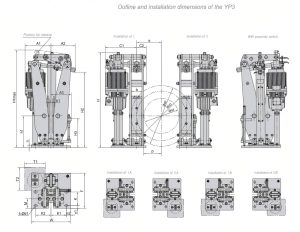

Dimensions and technical data of YP3 series disc brakes |

||||||||||||||||||||||||||||||||

| Thruster type | h1 | H | H1 | H2 | H3 | b | k | k1 | k2 | d1 | n | n1 | n2 | F | W | M | A1 | A2 | A3 | C1 | C2 | T1 | T2 | |||||||||

| A | B | A | B | A | B | A | B | |||||||||||||||||||||||||

| Ed1250-60 | 370 | 1115 | 1145 | 880 | 345 | 120 | 160 | 180 | 180 | 27 | 20 | 30 | 50 | 410 | 460 | 110 | 340 | 310 | 286 | 240 | 340 | 370 | 113 | 268 | 240 | 240 | 268 | |||||

| Ed2000-60 | ||||||||||||||||||||||||||||||||

| Ed3000-60 | ||||||||||||||||||||||||||||||||

| Relative Dimensions of brake disc | Thechn ical data (mm) | |||||||||||||||||||||||||||||||

| d2 Disc diameter |

b1 | S | d3 | 04 | e | p | Thruster | Disc Diameter | Weight (kg) |

|||||||||||||||||||||||

| Thruster type | Power (W) |

Rated Current(A) |

Weight (kg) |

630 | 710 | 800 | 900 | 1000 | 1250 | |||||||||||||||||||||||

| 630 | 30 | 0.7~1.3 | 500 | 310 | 250 | 170 | Max.Brake torque M=0.4 | |||||||||||||||||||||||||

| 710 | 30 | 580 | 390 | 290 | 210 | Ed1250-60 | 550 | 1.52 | 40 | 3750 | 4500 | 5000 | 5600 | 302 | ||||||||||||||||||

| 800 | 30 | 670 | 480 | 335 | 255 | Ed2000-60 | 750 | 1.98 | 40 | 6000 | 7100 | 8000 | 9100 | 10500 | 306 | |||||||||||||||||

| 900 | 30 | 770 | 580 | 385 | 305 | Ed3000-60 | 900 | 2.21 | 42 | 9000 | 10500 | 12000 | 13650 | 15600 | 20000 | 313 | ||||||||||||||||

| 1000 | 30 | 870 | 680 | 435 | 355 | Note:1)s=Brake clearance. 2)d4=Max.alowable couplingor hub diameter. 3)Averagefriction factor of standard friction materials |

||||||||||||||||||||||||||

| 1250 | 30 | 1120 | 930 | 560 | 480 | |||||||||||||||||||||||||||