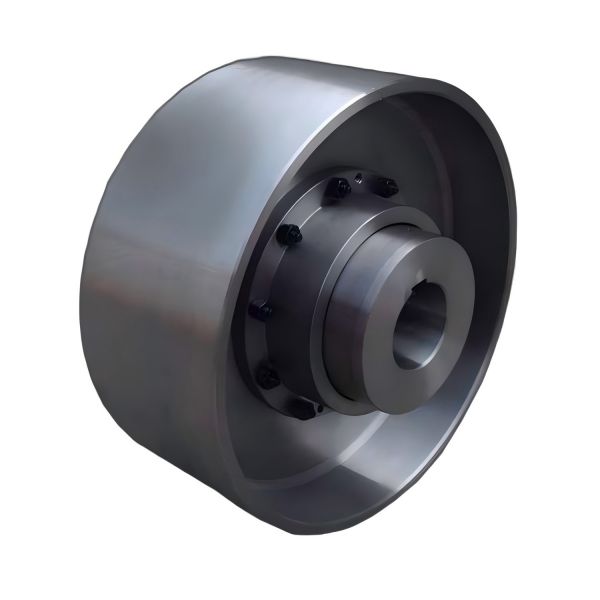

Crane brake wheel coupling

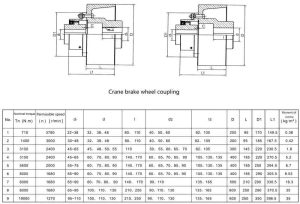

Crane Brake Wheel Coupling Parameters:

- Maximum Allowable Torque: 630 Nm to 125,000 Nm

- Maximum Speed: 4000 rpm to 950 rpm

- Brake Wheel Diameter: ∅160, ∅200, ∅250, ∅300, ∅315, ∅400, ∅500, ∅600, ∅630, ∅700, ∅800

- Coupling Material: ZG430-640, 45 steel

- Coupling Type: Brake wheel with half-tooth coupling

- Custom Options: You can provide your own drawings, and we will manufacture according to the specified dimensions.

The crane brake wheel coupling is a critical mechanical component used to connect the driving and driven shafts of a crane, allowing them to rotate together to transmit torque. Not only does this coupling play the role of transmitting power and motion, but it also provides a level of overload protection to prevent excessive load on the connected machinery. During crane operation, the brake wheel coupling serves a vital function in ensuring the safety and efficiency of lifting operations.

When designing and manufacturing the crane brake wheel coupling, several factors are considered to guarantee its performance and reliability. First, it must withstand the significant torque generated during lifting operations while also being durable and stable. Furthermore, due to the unique operating conditions cranes face, this coupling needs excellent wear resistance and corrosion resistance to adapt to various complex working environments.

When selecting and using a brake wheel coupling, it is essential to consider multiple factors, including the load size and nature, shaft alignment, and working environment. For instance, in cases where the load is steady and the shafts are precisely aligned, a rigid coupling may be suitable. However, in scenarios with large load fluctuations or frequent start-and-stop operations, a flexible coupling with cushioning and vibration-damping elements is preferable. Additionally, specific environmental factors, such as high or low temperatures or the presence of oil, acids, or alkalis, must be considered to avoid choosing unsuitable materials and structures.

In summary, the brake wheel coupling is an indispensable part of a crane system, and its performance and reliability directly impact the crane’s safe operation and working efficiency. Therefore, selecting and using the correct coupling type is crucial.

Video

Faq

Q1: What is a crane brake wheel coupling?

A: A crane brake wheel coupling connects the brake wheel to the crane’s drive shaft, ensuring smooth transmission of torque while enabling reliable braking performance.

Q2: What are the main functions of a brake wheel coupling?

A: It transmits rotational force, maintains alignment between the brake wheel and shaft, absorbs shock loads, and ensures the crane’s braking system operates safely and efficiently.

Q3: What materials are used for crane brake wheel couplings?

A: Typically, high-strength alloy steel or forged steel is used for durability, wear resistance, and the ability to withstand heavy loads in industrial crane applications.

Q4: How do I know which brake wheel coupling fits my crane?

A: Selection depends on shaft diameter, torque requirements, and brake wheel type. Our team at www.hnhlcrane.com can help you choose the correct coupling for your crane model.

Q5: How often should crane brake wheel couplings be inspected?

A: Regular inspection is recommended, especially in heavy-duty operations. Check for wear, misalignment, cracks, and proper lubrication to prevent unexpected failures.

Q6: Can crane brake wheel couplings be customized?

A: Yes, custom couplings are available for different sizes, torque ratings, and environmental conditions. OEM replacements and special designs can be provided on request via www.hnhlcrane.com.