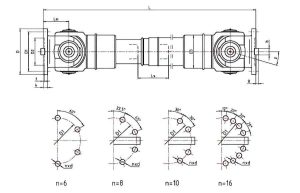

Cardan Shaft Coupling

Cardan Shaft Coupling Parameters:

- Maximum Allowable Torque: 2.5 kN.m to 1000 kN.m

- Shaft Deflection Angle: ≤ 25°, ≤ 15°

- Flange Diameter: ∅100 to ∅550

- Length: 405 mm to 2300 mm

- Length Extension Range: 55 mm to 240 mm

The Cardan Shaft Coupling is a high-performance coupling with numerous advantages, making it particularly suitable for mechanical systems that require large-angle compensation, high load capacity, efficient transmission, and smooth operation.

The main features of the Cardan Shaft Coupling include:

- Large-Angle Compensation Capability: The Cardan Shaft Coupling offers significant angular compensation, with a shaft deflection angle of 15-25 degrees. This makes it highly applicable in mechanical transmission systems requiring substantial angle adjustments.

- Compact and Rational Structure: The integrated fork design enhances load reliability while ensuring a compact structure, making it ideal for installations in confined spaces.

- High Load Capacity: Compared to other types of couplings with the same rotation diameter, the SWC universal coupling can transmit greater torque, especially suitable for equipment with restricted rotation diameters.

- High Transmission Efficiency: With a transmission efficiency of 98-99.8%, it is well-suited for high-power transmission scenarios, offering significant energy-saving benefits.

- Smooth Operation: The coupling provides stable load transmission, low noise, and easy assembly and maintenance, which improves the overall quality and longevity of the equipment.

When installing and using the Cardan Shaft Coupling, consider the following points:

- Ensure the consistency of universal shaft performance and avoid changing the universal shaft status arbitrarily.

- Take appropriate protective measures to ensure safety.

- During installation, align the flange fork position carefully, avoiding unintentional movement or replacement of the spline.

- For telescopic universal shafts, securely fix the flange of the connected component to the universal shaft.

- If the Cardan Shaft Coupling has been stored for over six months, re-lubricate it before use.

In summary, due to its exceptional performance and reliability, the Cardan Shaft Coupling plays a crucial role in various industrial applications, especially in situations requiring large-angle compensation, high torque transmission, and high-efficiency power transfer.

SWC-type Cross Shaft Universal Coupling basic parameters and main dimensions

| Type | Rotation diameter D (mm) |

Nominal torque Tn (KN.m) |

Fatigue torque Tf (KN.m) |

Axis angle β (°) |

Scalable capacity Ls (mm) |

Size (mm) | Moment of Inertia (kg/m²) |

Weight (kg) |

|||||||||||

| Lmin | D1(js11) | D2 (H7) |

D3 | Lm | n×∅d | k | t | b (h9) |

g | Lmin | Increase 100mm |

Lmin | Increase 100mm |

||||||

| SWC100BH | 100 | 2.5 | 1.25 | ≤25 | 55 | 405 | 84 | 57 | 60 | 55 | 6×∅9 | 7 | 2.5 | / | / | 0.004 | 0.0002 | 6.1 | 0.35 |

| SWC120BH | 120 | 5 | 2.5 | ≤25 | 80 | 485 | 102 | 75 | 70 | 65 | 8×∅11 | 8 | 2.5 | / | / | 0.001 | 0.0004 | 10.8 | 0.55 |

| SWC150BH | 150 | 10 | 5 | ≤25 | 80 | 590 | 130 | 90 | 89 | 80 | 8×∅13 | 10 | 3 | / | / | 0.042 | 0.0016 | 24.5 | 0.85 |

| SWC180BH | 180 | 22.4 | 11.2 | ≤15 | 100 | 840 | 155 | 105 | 114 | 110 | 8×∅17 | 17 | 5 | 24 | 7 | 0.175 | 0.007 | 70 | 2.8 |

| SWC200BH | 200 | 36 | 18 | ≤15 | 110 | 860 | 170 | 120 | 133 | 115 | 8×∅17 | 17 | 5 | 28 | 8 | 0.314 | 0.013 | 98 | 3.7 |

| SWC225BH | 225 | 56 | 28 | ≤15 | 140 | 920 | 196 | 135 | 152 | 120 | 8×∅17 | 20 | 5 | 32 | 9 | 0.538 | 0.023 | 122 | 4.9 |

| SWC250BH | 250 | 80 | 40 | ≤15 | 140 | 1035 | 218 | 150 | 168 | 140 | 8×∅19 | 25 | 6 | 40 | 12.5 | 0.966 | 0.028 | 172 | 5.3 |

| SWC280BH | 285 | 120 | 58 | ≤15 | 140 | 1190 | 245 | 170 | 194 | 160 | 8×∅21 | 27 | 7 | 40 | 15 | 2.011 | 0.051 | 263 | 6.3 |

| SWC315BH | 315 | 160 | 80 | ≤15 | 140 | 1315 | 280 | 185 | 219 | 180 | 10×∅23 | 32 | 8 | 40 | 15 | 3.605 | 0.008 | 382 | 8 |

| SWC350BH | 350 | 225 | 110 | ≤15 | 150 | 1440 | 310 | 210 | 245 | 194 | 10×∅23 | 35 | 8 | 50 | 16 | 5.316 | 0.146 | 532 | 11.5 |

| SWC390BH | 390 | 320 | 160 | ≤15 | 170 | 1590 | 345 | 235 | 267 | 215 | 10×∅25 | 40 | 8 | 70 | 18 | 12.16 | 0.222 | 738 | 15 |

| SWC440BH | 440 | 500 | 250 | ≤15 | 190 | 1875 | 390 | 255 | 325 | 260 | 16×∅28 | 42 | 10 | 80 | 20 | 21.42 | 0.474 | 1190 | 21.7 |

| SWC490BH | 490 | 700 | 350 | ≤15 | 190 | 1985 | 435 | 275 | 351 | 270 | 16×∅31 | 47 | 12 | 90 | 22.5 | 34.1 | 0.69 | 1542 | 27.3 |

| SWC550BH | 550 | 1000 | 500 | ≤15 | 240 | 2300 | 492 | 320 | 426 | 305 | 16×∅31 | 50 | 12 | 100 | 22.5 | 68.92 | 1.357 | 2380 | 34 |