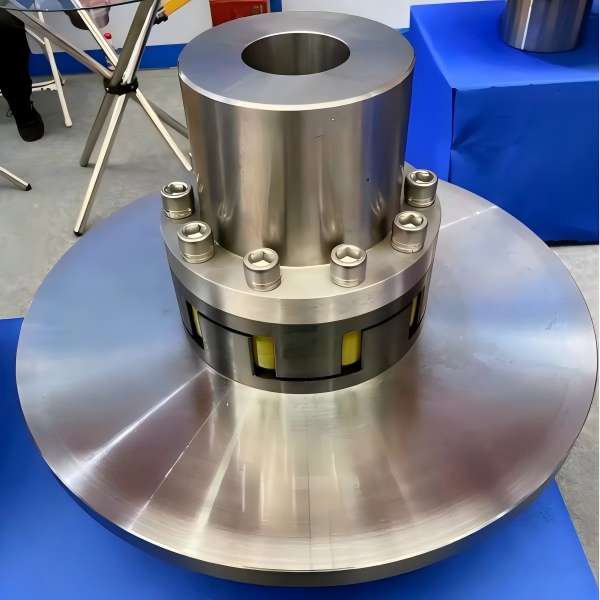

Brake wheel plum elastic coupling

MLLZ Brake Wheel Plum Elastic Coupling Specifications:

- Maximum allowable torque: 250 Nm to 31,500 Nm

- Maximum speed: 4250 r/min to 950 r/min

- Shaft hole diameter: ∅25 to ∅200

- Brake wheel diameter: ∅160, ∅200, ∅250, ∅300, ∅315, ∅400, ∅500, ∅600, ∅630, ∅700, ∅800

- Custom specifications: We can manufacture the coupling based on your provided drawings.

The Brake Wheel Plum Elastic Coupling is a high-performance coupling that combines high reliability, excellent vibration and shock absorption, and superior wear and oil resistance. This coupling is particularly suitable for working environments that involve frequent starts, forward and reverse rotation, medium to high speeds, and moderate torque. It is widely used in fields such as metallurgy, mining, petroleum, chemical engineering, hoisting, transportation, light industry, textiles, pumps, and fans. Its main features and advantages include:

- High Reliability: The MLLZ Brake Wheel Plum Elastic Coupling provides excellent vibration damping and shock absorption, effectively reducing mechanical vibrations and impacts, thus enhancing the stability and longevity of equipment.

- Wear and Oil Resistance: The coupling uses high-strength polyurethane elastic elements, offering excellent wear and oil resistance, making it ideal for harsh working environments.

- Simple Structure and Easy Maintenance: The coupling has a simple structure, compact radial size, light weight, and low rotational inertia, making it suitable for medium to high-speed applications. Moreover, it does not require lubrication, reducing maintenance efforts and allowing for continuous long-term operation.

- Strong Compensation Capability: It features large axial, radial, and angular compensation abilities, adapting to relative displacements between shafts and ensuring the stable operation of the equipment.

- Wide Applicability: The coupling is suitable for connecting coaxial shafts, frequent start-ups, forward and reverse rotation changes, medium-speed, moderate torque transmission shafts, and equipment requiring high operational reliability.

Additionally, the MLLZ Brake Wheel Plum Elastic Coupling has a wide operating temperature range, from -35°C to +80°C, and the nominal torque transmission range is from 250 to 31,500 Nm, with a permissible speed range of 950 to 4250 r/min. This coupling offers a variety of specifications and sizes to meet different application needs.

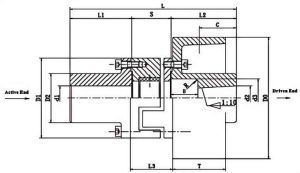

The parameters and dimensions of the MLLZ Brake Wheel Plum Elastic Coupling

| Type | Nominal torque | Permissible speed | Shaft hole diameter d1 ,d2 |

Shaft hole length:L1,L2 | L | S | L3 | C | D1 | D2 | B | d3 | R | D0×T | Elastic parts type | Weight | Moment of Inertia |

| N.m | r/min | mm | mm | mm | kg | kg.m² | |||||||||||

| MLLZ4-200(160) | 250 | 4250 | 25,28 | 62 | 176 | 52 | 56 | 18 | 105 | 65 | 14 | 38 | 1.5 | 200×85 | MT4-b | 12.98 | 0.049 |

| 30,32,35,38 | 82 | 216 | 38 | ||||||||||||||

| 40,42 | 112 | 276 | 68 | ||||||||||||||

| MLLZ5 -200 | 400 | 3800 | 30,32,35,38 | 82 | 224 | 60 | 64 | 38 | 125 | 80 | 18 | 48 | 1.5 | 200×85 | MT5-b | 6.92 | 0.058 |

| 40,42,45,48 | 112 | 284 | 68 | ||||||||||||||

| MLLZ6 -250 (200) | 630 | 3050 | 35,38 | 82 | 231 | 67 | 71 | 28 | 145 | 85 | 22 | 65 | 1.5 | 250×105 | MT6-b | 24.93 | 0.15 |

| 40,45,50,55 | 112 | 291 | 58 | ||||||||||||||

| MLLZ7-315(250) | 1120 | 2400 | 40,50,55 | 112 | 291 | 67 | 71 | 42 | 172 | 110 | 28 | 80 | 2 | 315×135 | MT7-b | 43.89 | 0.41 |

| 60,63,65 | 142 | 351 | 72 | ||||||||||||||

| MLLZ8 -400 (315) | 1800 | 1900 | 50,55 | 112 | 300 | 76 | 81 | 24 | 200 | 135 | 28 | 95 | 2.5 | 400×170 | MT8-b | 73.97 | 1.24 |

| 60,65,70,75 | 142 | 360 | 54 | ||||||||||||||

| MLLZ9 -500 | 2800 | 1650 | 60,65,70,75 | 142 | 364 | 80 | 86 | 34 | 230 | 160 | 40 | 105 | 2.5 | 500×210 | MT9-b | 121.5 | 3.34 |

| 80,85,90,95 | 172 | 424 | 64 | ||||||||||||||

| MLLZ10 -500(400) | 4500 | 1500 | 70,75 | 142 | 379 | 95 | 101 | 34 | 262 | 180 | 40 | 140 | 2.5 | 500×210 | MT10-b | 157.9 | 3.6 |

| 80,85,90,95 | 172 | 439 | 64 | ||||||||||||||

| 100,110 | 212 | 519 | 104 | ||||||||||||||

| MLLZ11 -630 | 7100 | 1350 | 80,85,90,95 | 172 | 455 | 111 | 117 | 36 | 300 | 200 | 40 | 150 | 3 | 630×265 | MT11-b | 232.5 | 9.51 |

| 100,110 | 212 | 535 | 76 | ||||||||||||||

| MLLZ12 -710 | 11200 | 1200 | 90,95 | 172 | 468 | 124 | 130 | 19 | 360 | 225 | 45 | 160 | 3 | 710×300 | MT12-b | 346.2 | 17.61 |

| 100,110,120,125 | 212 | 548 | 59 | ||||||||||||||

| 130 | 252 | 628 | 99 | ||||||||||||||

| MLLZ13 -800 | 12500 | 1100 | 100,110,120,125 | 212 | 548 | 124 | 130 | 39 | 400 | 225 | 50 | 160 | 4 | 800×340 | MT13-b | 450.6 | 29.96 |

| 130,140 | 252 | 628 | 79 | ||||||||||||||

| MLLZ14-800 | 20000 | 1050 | 110,120,125 | 212 | 548 | 124 | 130 | 39 | 460 | 260 | 50 | 180 | 4 | 800×340 | MT14-b | 495 | 32.71 |

| 130,140,150 | 252 | 628 | 79 | ||||||||||||||

| MLLZ15 -800 | 25000 | 1000 | 120.125 | 212 | 559 | 135 | 141 | 39 | 500 | 300 | 60 | 215 | 5 | 800×340 | MT15-b | 558 | 36.38 |

| 130,140,150 | 252 | 639 | 79 | ||||||||||||||

| 160,170,180 | 302 | 739 | 129 | ||||||||||||||

| MLLZ16 -800 | 31500 | 950 | 130,140,150 | 252 | 639 | 135 | 141 | 79 | 500 | 340 | 70 | 250 | 5 | 800×340 | MT16-b | 608 | 39.47 |

| 160,170,180 | 302 | 739 | 129 | ||||||||||||||

| 190,200 | 352 | 839 | 179 | ||||||||||||||