Billet crane clamps

Billet crane clamps,Billet lifting clamp,Billet Clamps,Billet crane clamps manufacturer,billet lifting clamps china supplier,Special Crane Spreader

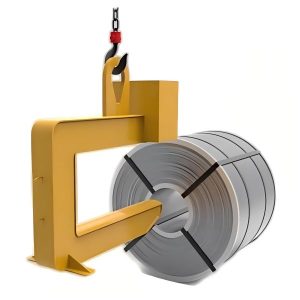

Billet Crane Clamps Overview

Billet crane clamps are specialized tools designed for lifting and transporting billets, widely used in steel mills, ports, terminals, and other facilities. Utilizing the principle of leverage, these clamps securely grip billets with flexibility and ensure safe handling operations.

Components of Billet Crane Clamps

- Lifting Beam:Connects to the overhead crane hook.

- Linkage Rod:Links the lifting beam to the clamp arms.

- Opening and Closing Mechanism:Controls the clamp’s open and close actions.

- Synchronizer:Ensures the synchronized movement of all clamp arms.

- Clamp Arms:Provide structural support for gripping billets.

- Support Plate:Offers additional stability.

- Clamp Teeth:Grip the billet securely during operations.

Key Features of Billet Crane Clamps

- Reliable Clamping:Leverage mechanisms generate sufficient clamping force. The friction force created by this clamping securely lifts billets.

- Robust Structure:Clamp arms and linkage rods are crafted in I-beam or T-beam structures, ensuring high rigidity and extended lifespan.

- High Adaptability:Suitable for lifting single-layer or multi-layer billets, as well as multiple square billets simultaneously.

- Flexible Operation:Equipped with gravity-actuated opening and closing mechanisms, enabling flexible movements without requiring external force.

- Durability and Wear Resistance:Clamp teeth are forged from high-strength alloy steel, heat-treated, and hard-faced with carbide to deliver excellent hardness, strength, and toughness.

- Lubrication System:For hot billet handling, lubrication is achieved through oil injection holes. For normal temperature billets, lubrication is maintained using oil reservoirs.

Usage and Maintenance Guidelines

- Regular Lubrication:Periodically lubricate the opening and closing mechanisms and other key components to maintain smooth operations and prolong the lifespan of the clamps.

- Operator Training:Ensure operators are properly trained in the correct use and maintenance of the clamps to avoid accidents or damage caused by improper operation.

- Inspection and Maintenance:Routinely check for wear and tear, especially on critical components like clamp teeth and linkage rods, and replace or repair as needed.

Billet crane clamps provide a reliable, durable, and efficient solution for handling billets in demanding industrial environments, ensuring safe and effective material transport.

Dimensions and parameters

| Lifting capacity (t) |

w (mm) |

h (mm) |

L (mm) |

Maximum dimensions(mm) | |

| W | H | ||||

| 5 | 450-600 | 250 | 800 | 1200 | 1800 |

| 5 | 650-1000 | 250 | 800 | 1500 | 2300 |

| 8 | 150-450 | 250 | 1200 | 2000 | 2400 |

| 8 | 450-600 | 250 | 1200 | 1600 | 2500 |

| 8 | 450-750 | 300 | 1200 | 1600 | 2200 |

| 10 | 450-900 | 300 | 1500 | 1900 | 2600 |

| 10 | 650-1000 | 300 | 1500 | 1600 | 2600 |

| 10 | 700-1100 | 300 | 1500 | 1700 | 2600 |

| 12 | 450-750 | 300 | 2000 | 1800 | 2400 |

| 12 | 235-800 | 300 | 2000 | 2300 | 3000 |

| 16 | 600-1100 | 300 | 2500 | 2400 | 3100 |

| 16 | 850-1250 | 300 | 2500 | 2000 | 3000 |

| 20 | 800-1300 | 300 | 3000 | 2200 | 3400 |

| 20 | 950-1400 | 300 | 3000 | 2500 | 3500 |

| 20 | 1100-1600 | 300 | 3000 | 2400 | 3700 |

| 25 | 1000-1600 | 600 | 3000 | 3000 | 3900 |

| 25 | 1250-1750 | 450 | 3000 | 2800 | 3900 |

| 32 | 700-1350 | 450 | 3000 | 2900 | 4000 |

| 32 | 750-1400 | 450 | 3000 | 2800 | 4200 |

| 32 | 650-1500 | 450 | 3000 | 3400 | 4600 |

| 32 | 900-2150 | 600 | 3000 | 4400 | 6000 |

| 32 | 1000-2300 | 600 | 3000 | 4700 | 6300 |

| 40 | 850-1600 | 450 | 3500 | 3500 | 4900 |

| 40 | 1250-1750 | 450 | 3500 | 3000 | 3000 |

| 40 | 1600-2150 | 450 | 3500 | 3300 | 4300 |

| 50 | 1250-2150 | 450 | 4000 | 4000 | 5600 |

| 50 | 1850-2500 | 450 | 4000 | 3800 | 5000 |

| 50 | 1200-2750 | 750 | 4000 | 5600 | 7600 |

| 63 | 2050-2750 | 600 | 4000 | 4300 | 5800 |

| 80 | 750-1650 | 900 | 4500 | 5300 | 7100 |